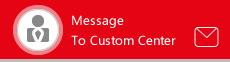

Automotive Lighting Vibration Welding Machine

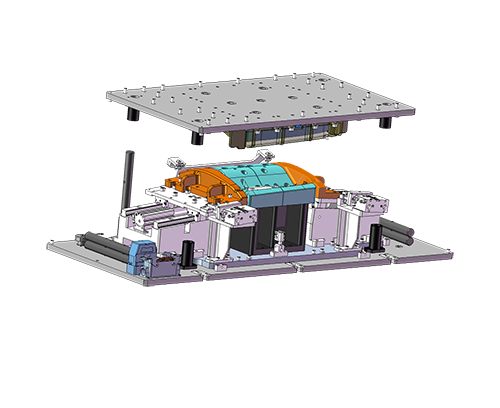

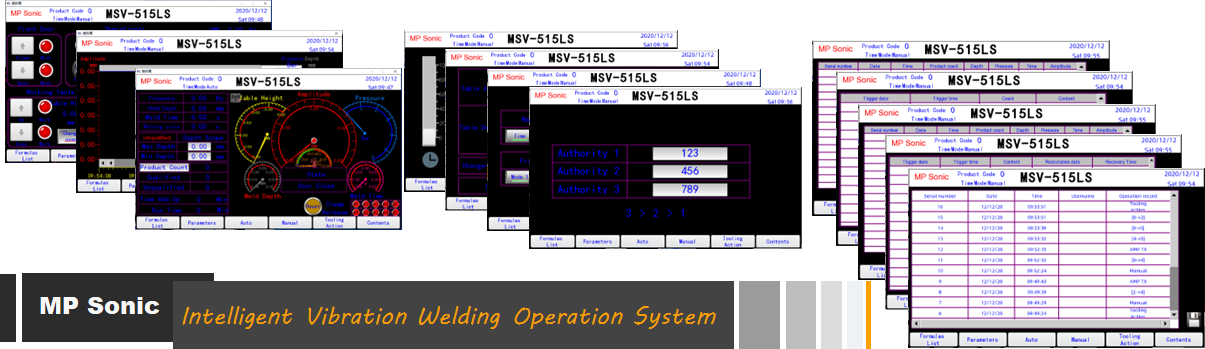

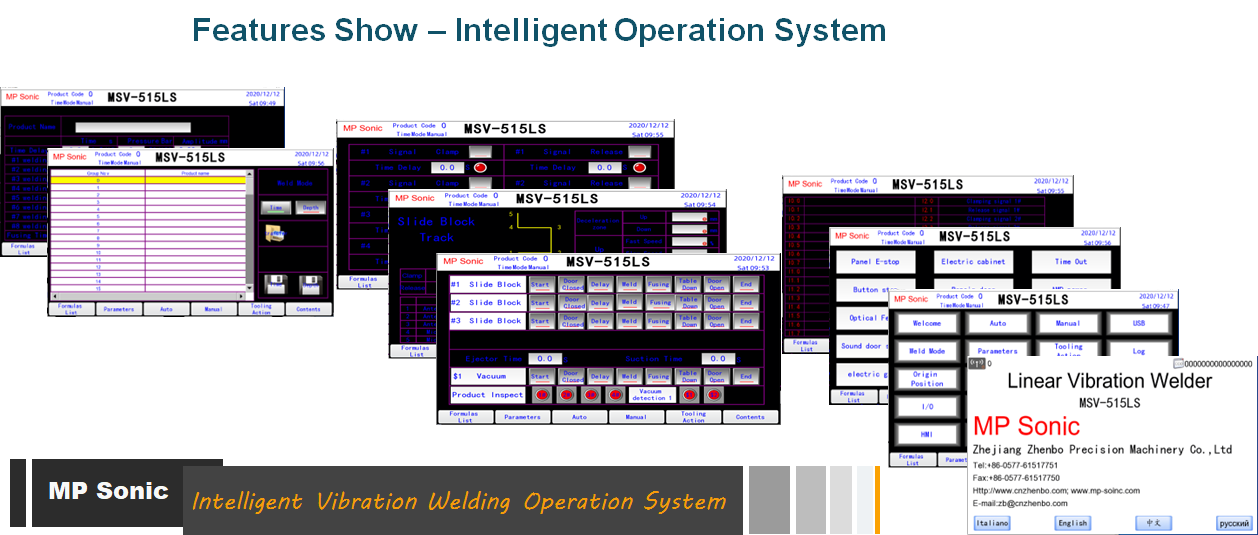

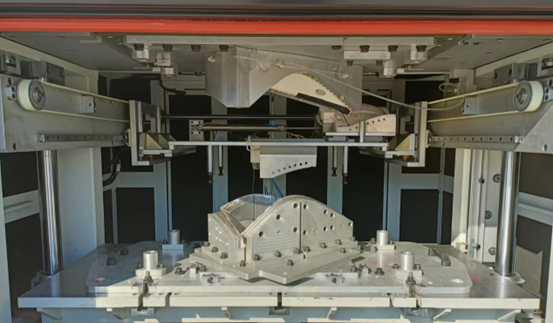

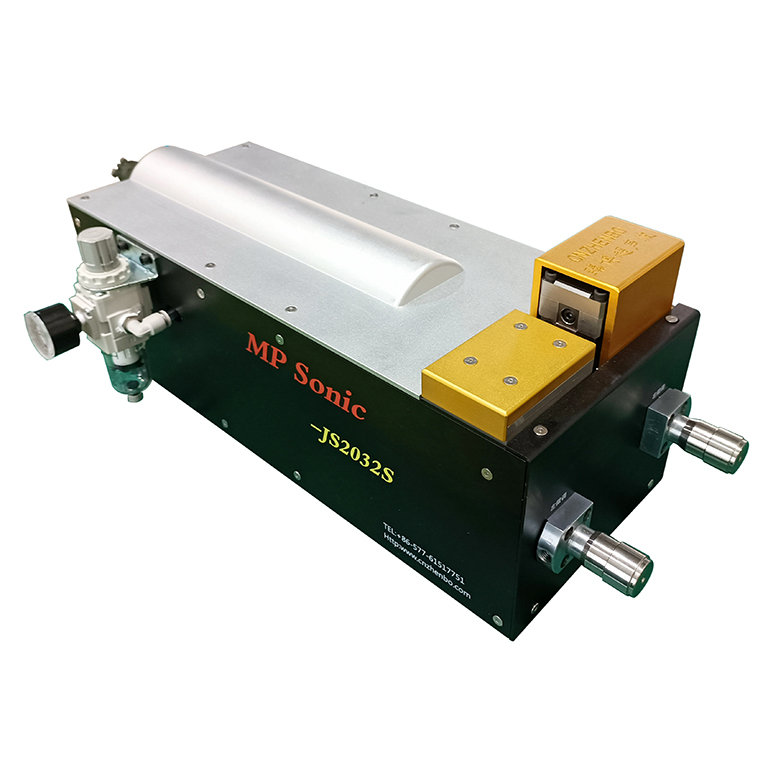

MSV-830LS-IR-SF is a vibration welding machine designed for automotive lighting joining specially. Machine applies MP Sonic SF series vibration system reach linear vibration frequency max to 365Hz which realizes welding in amplitude minimum to 0.3mm, by which maximum reduce the dirt inside automotive lamps during vibration friction of between material, as well reaches vibration friction welding at joining surface with bevel max to 40o.

Vibration welder MSV-830LS-IR-SF is with vibration loading ability for upper jig weight max to 100KG, which can be applied for tail lamps welding with double-cavities designed welding tooling. Machine specification is enhanced for through-type rear lighting welding. Servo hydraulic system is designed specially for machine to control and force welding in high seed, high precision and high clamp force, and enhances the life time of applied hydraulic oil.

IR (Infrared) pre-heating system is designed for machine to meet customer’s special demand in welding operation to meet more challenging requirement.

English

English