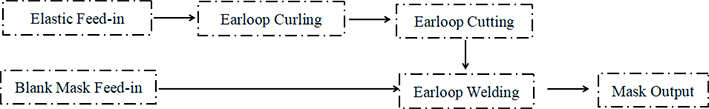

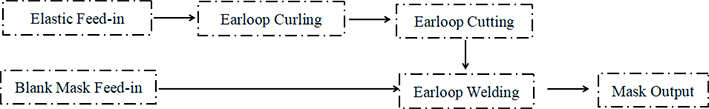

I. Material Flow:

II. Function and features:

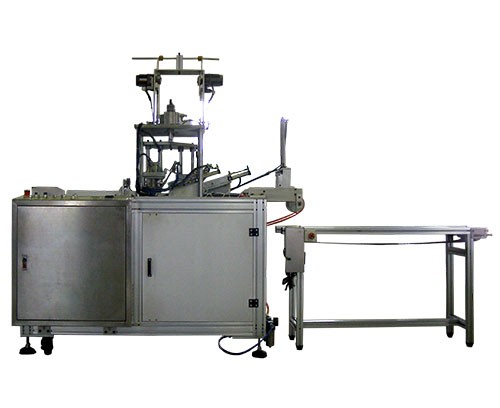

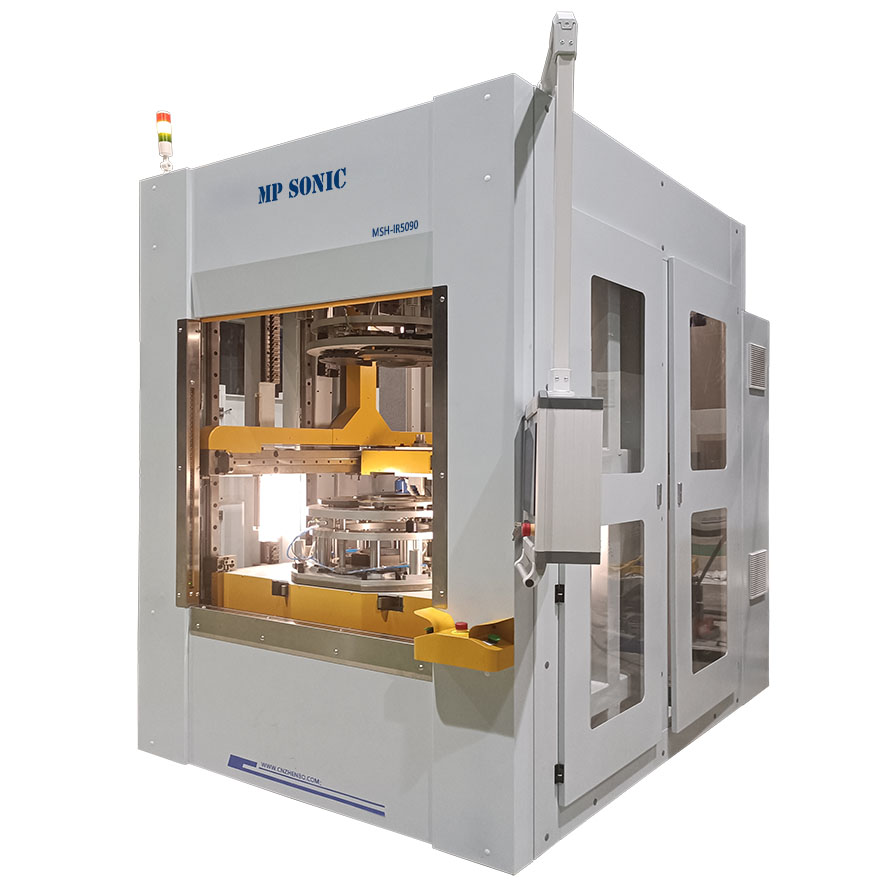

1. Machine is rigid and rustproof designed for duration;

2. Mask conveying controlled by servo motor in precision;

3. Guide rail guided mask conveying in smooth motion;

4. Positioning mechanism is designed to ensure mask location in precision with no moving;

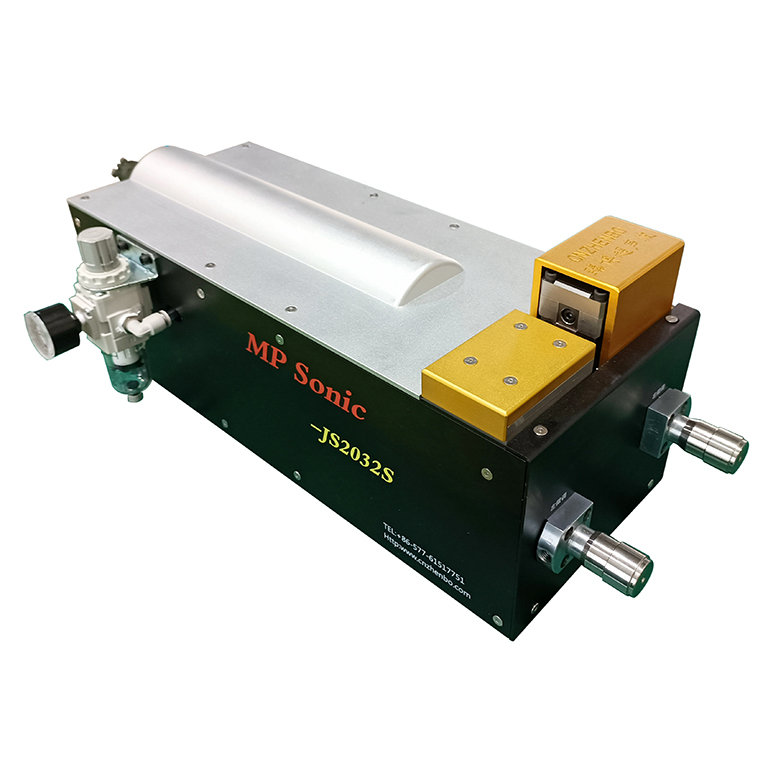

5. Two ultrasonic system is applied to weld earloop ensuring reliability welding and capacity;

6. Adjustment earloop curler designed for earloop length adjustment basing mask design;

7. Earloop is fed-in by servo motor to control earloop length in accuracy;

8. Counters is equipped to machine for output count automatically.

III. Machine Specification:

1. Power Source: 220V 1P AC 50/60Hz;

2. Air Source: 0.6~0.8MPa;

3. Machine Dimension: L1800mm*W900mm*H1850mm;

4. Output Capacity: 35~50PCs/Minute.

IV. Mask Specification:

Length of mask blank: 175mm(adult), 145mm(child)

Width mask blank: 90—95mm

Length of ear-loop: For adult-170mm(max , including welding spot); For children-150mm (max, including welding spot), adjustable as requests.

Distance of welding spot at one side: 80mm

English

English