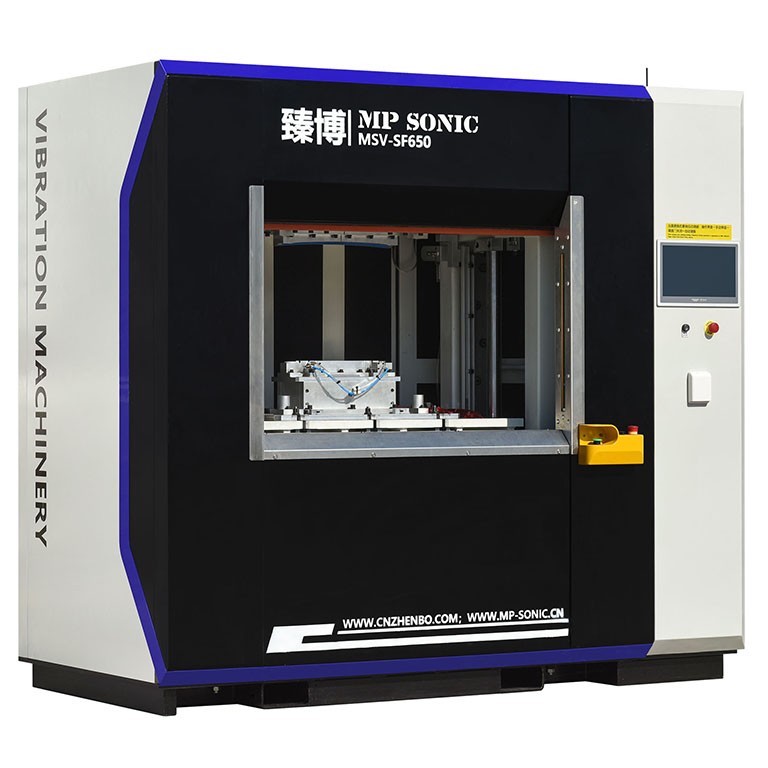

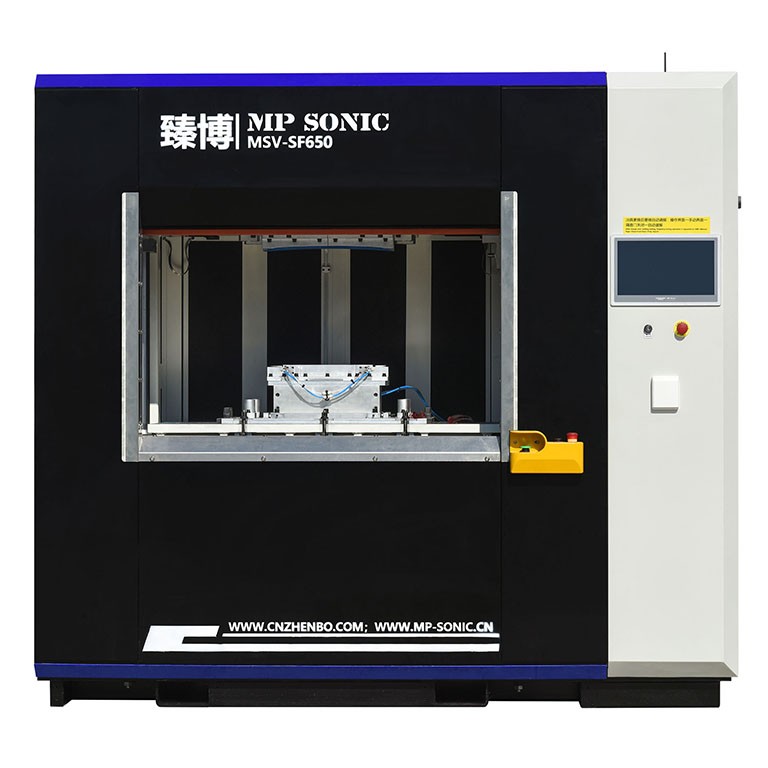

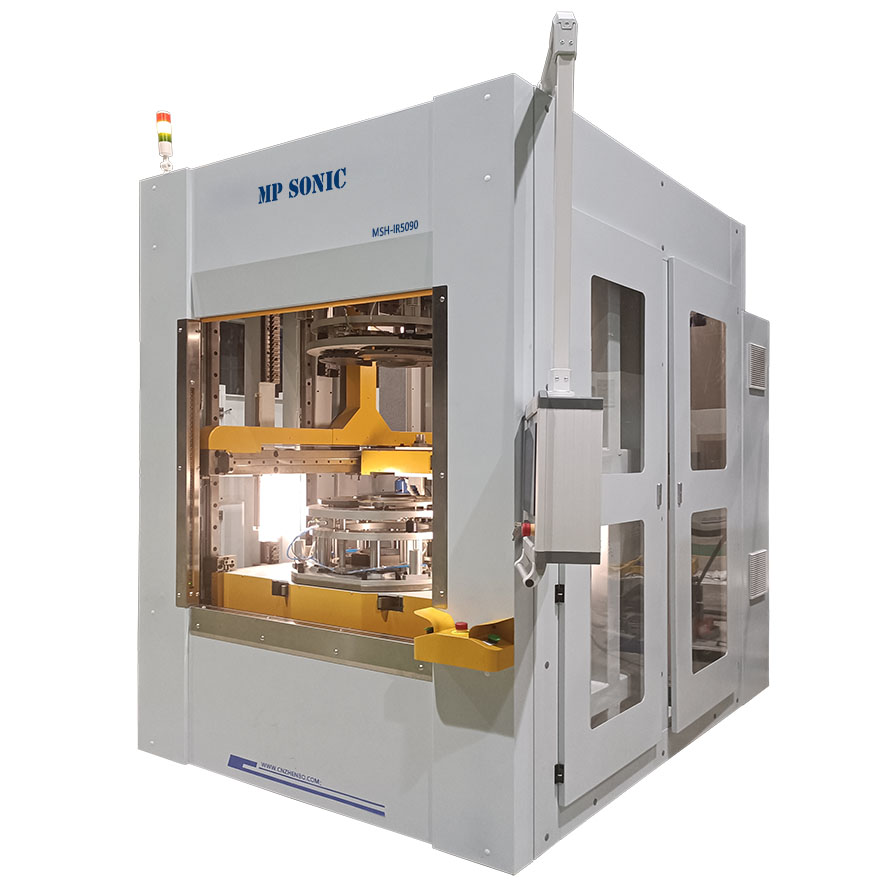

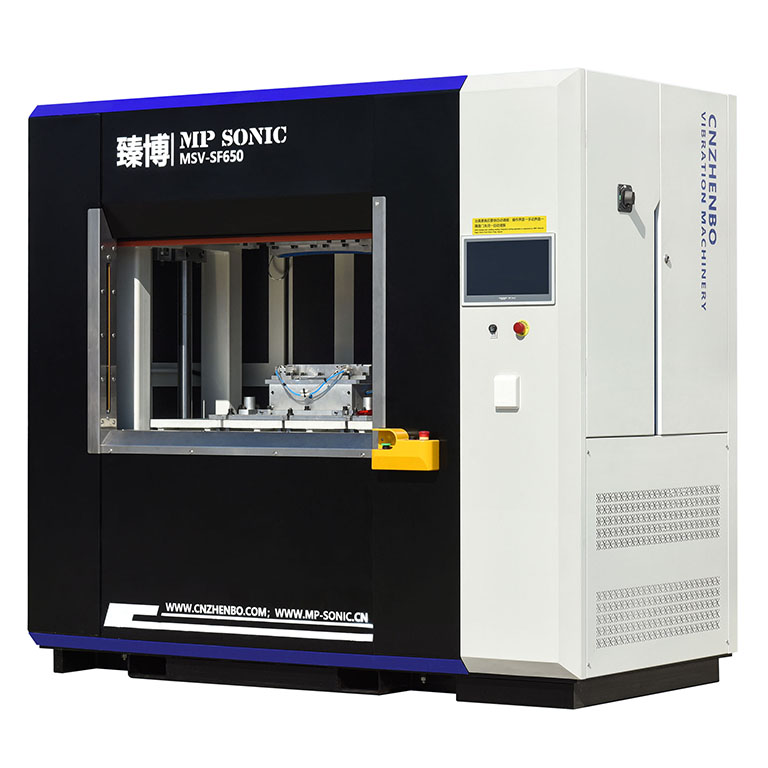

MSV-SF Series vibration welding machine welding

machine applies the newest Joining technology, SFVW technology, developed by CNZHENBO|MP Sonic to realize the excellent vibration plastic welding.

SFVW means super-high frequency vibration welding technology. SFVW system realizes vibration welding with

frequency as high as 365Hz, which is around 100Hz higher than the traditional vibration

welding frequency. With the super-high frequency, thermoplastic parts can case

enough energy by linear vibration friction to melt material in amplitude as short

as 0.2mm, which reduce the limit to parts geometric design and material dust generated

by friction.

SFVW technology normally is applied for welding parts in high requirement

of outlook or complex geometric design, especially the best choice for

automotive lamp welding.

MSV-SF series vibration welding can be forced by hydraulic system or

servo motor system. Machine applies MP Sonic intelligent operation system to

control, providing machine with multiple function to meet different requirement

by different material characteristics or geometric design.

I. Technical advantage:

A. Realize cleaning vibration welding without

pre-heating, comparing traditional CVT in lower frequency, it is with

advantages of high efficiency, high stability in welding performance, lower power

consumption and lower welding tooling cost; while comparing with synchronized

laser welding, it with the advantage of lower equipment cost, lower maintenance

cost and lower limit in plastic material;

B. SFVW can realized vibration welding with

slope angle max to 45。, minimizing

the limit to products geometric design;

C. With high frequency max to 365Hz, SFVW realize

welding in amplitude as short as 0.2mm, which minimizing the space requested on

parts design for vibration, making it more easy for products design.

II. Main Features:

Covers all features with MSV-LS series vibration

welding machine.

III. Optional Feature:

-S: pure servo control to lift-table Servo Motor.

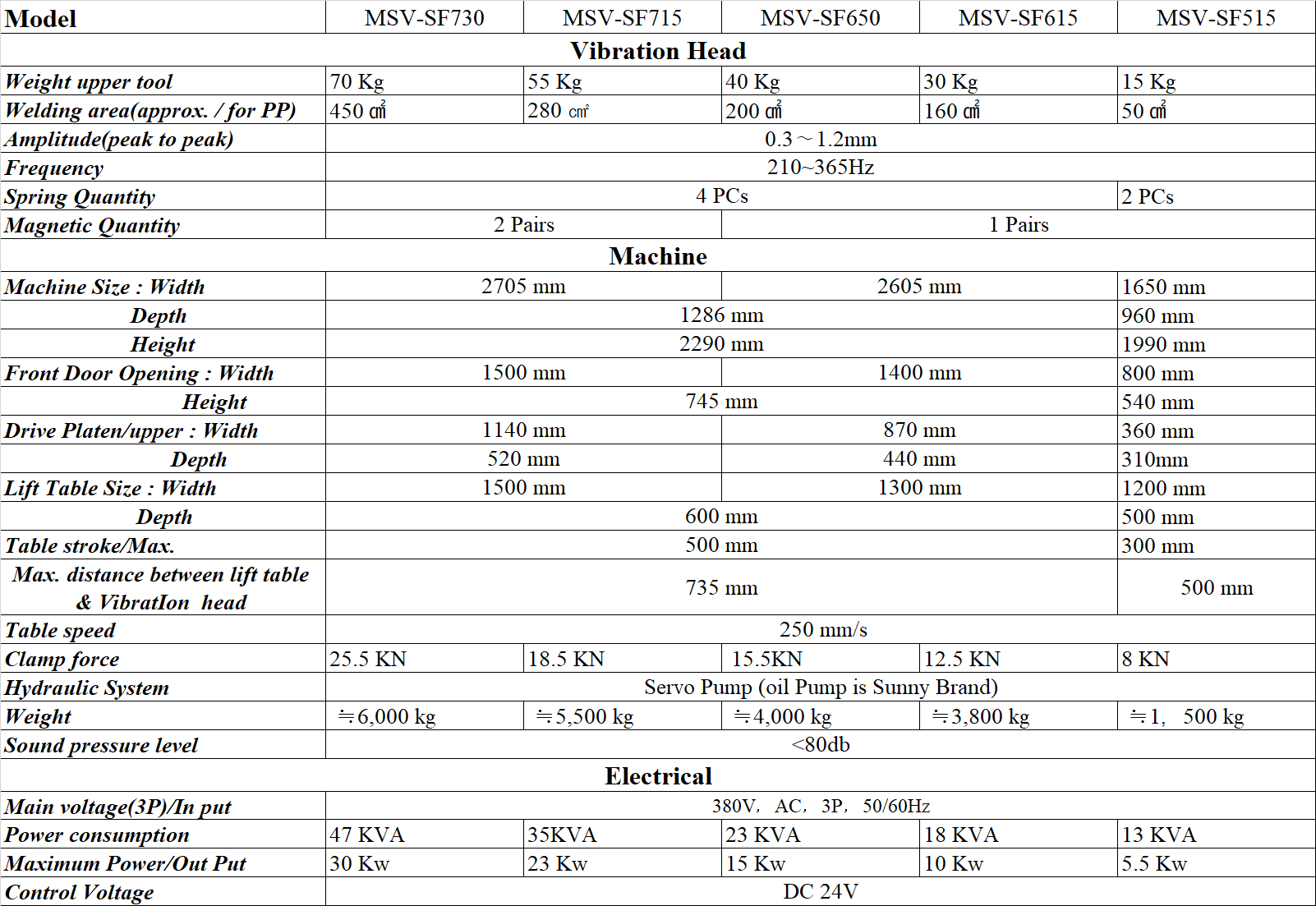

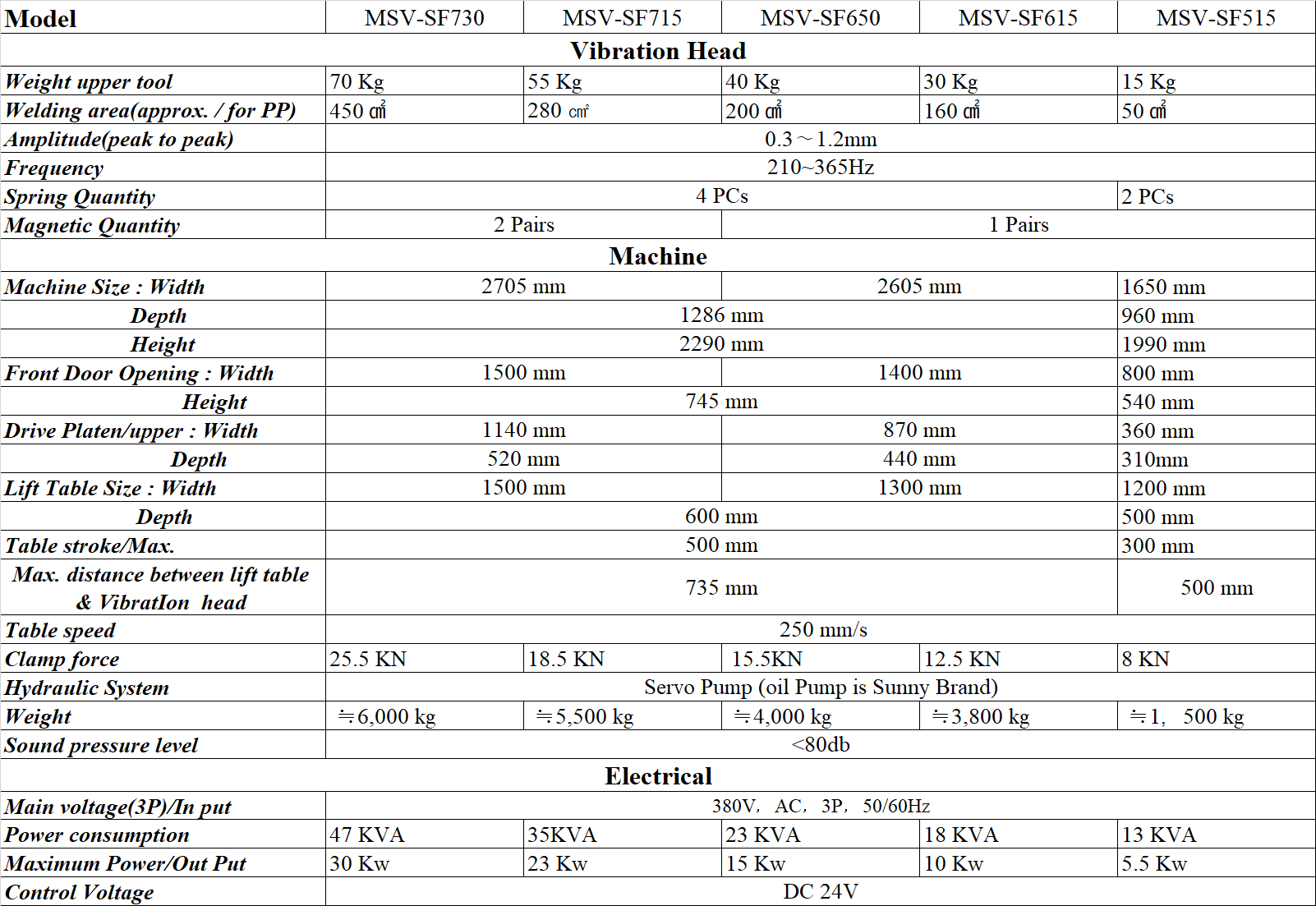

III. Technical Parameter Sheet.

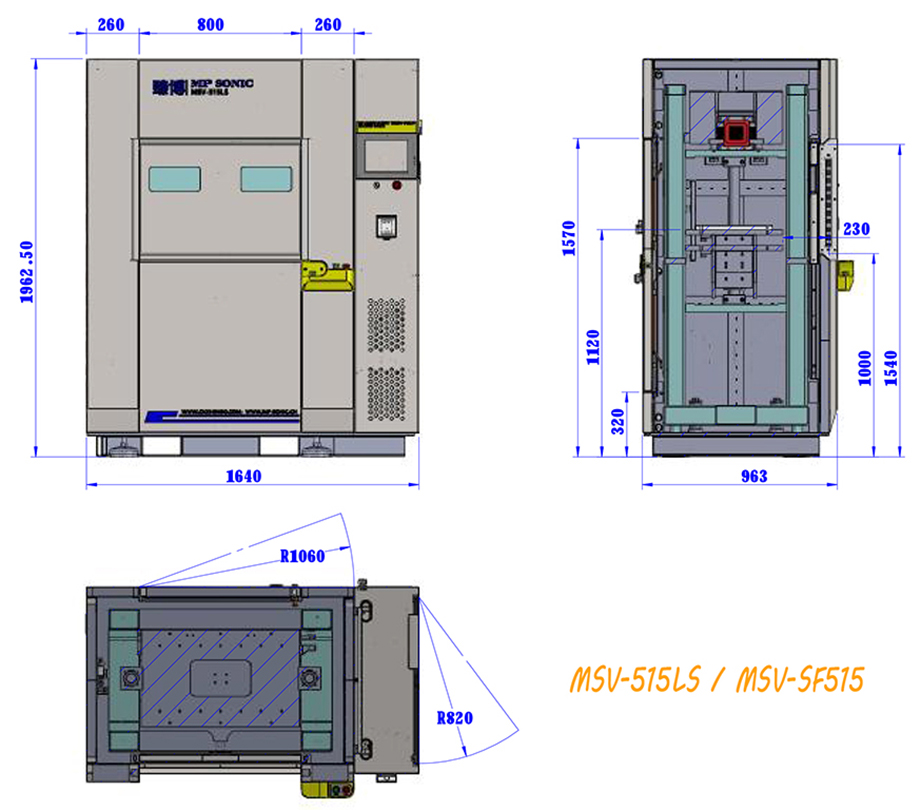

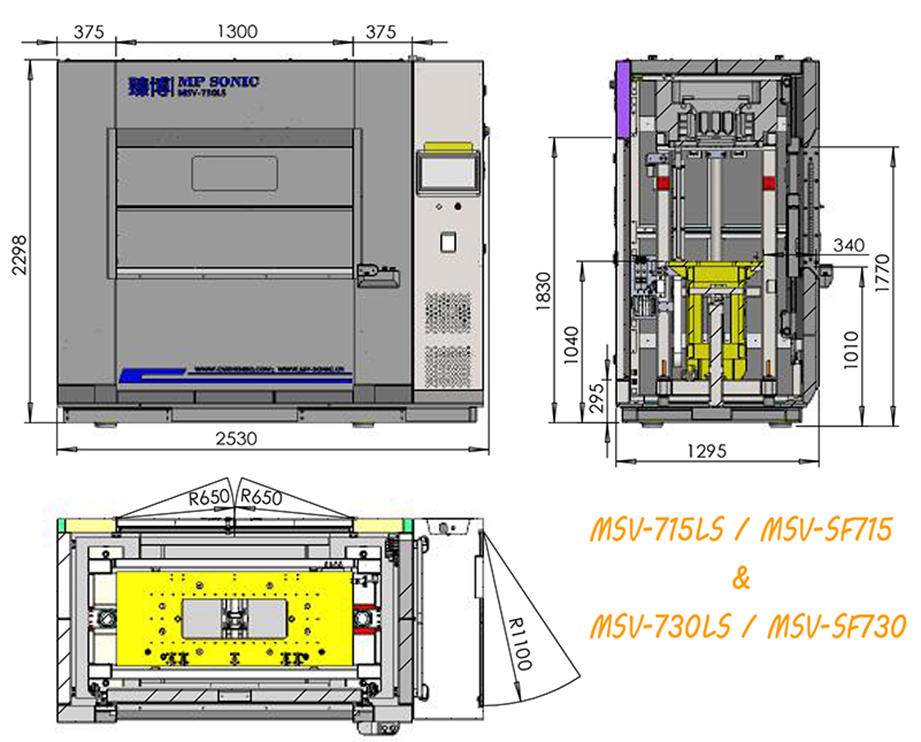

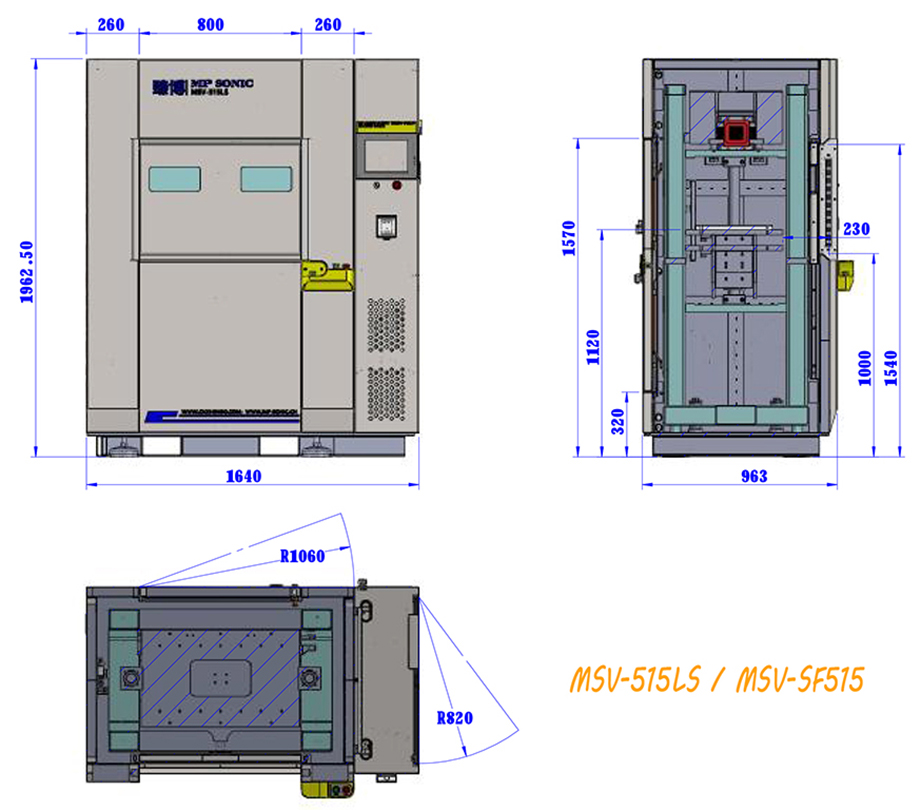

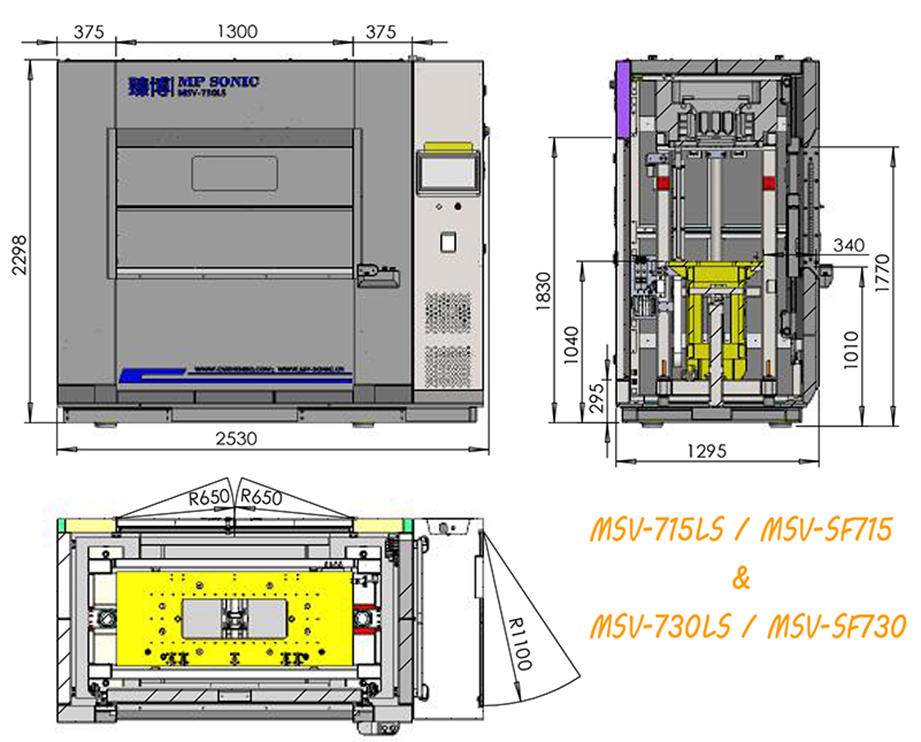

IV. Machine Measurement Layout.

English

English