N95 Cup Mask Line

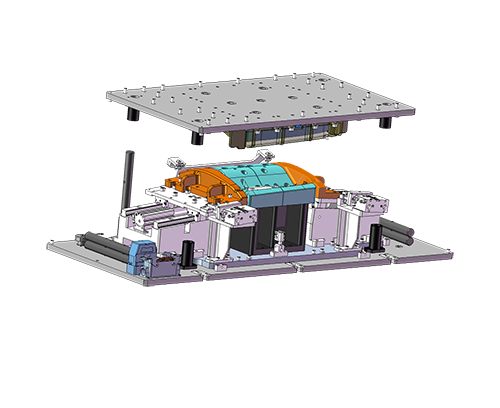

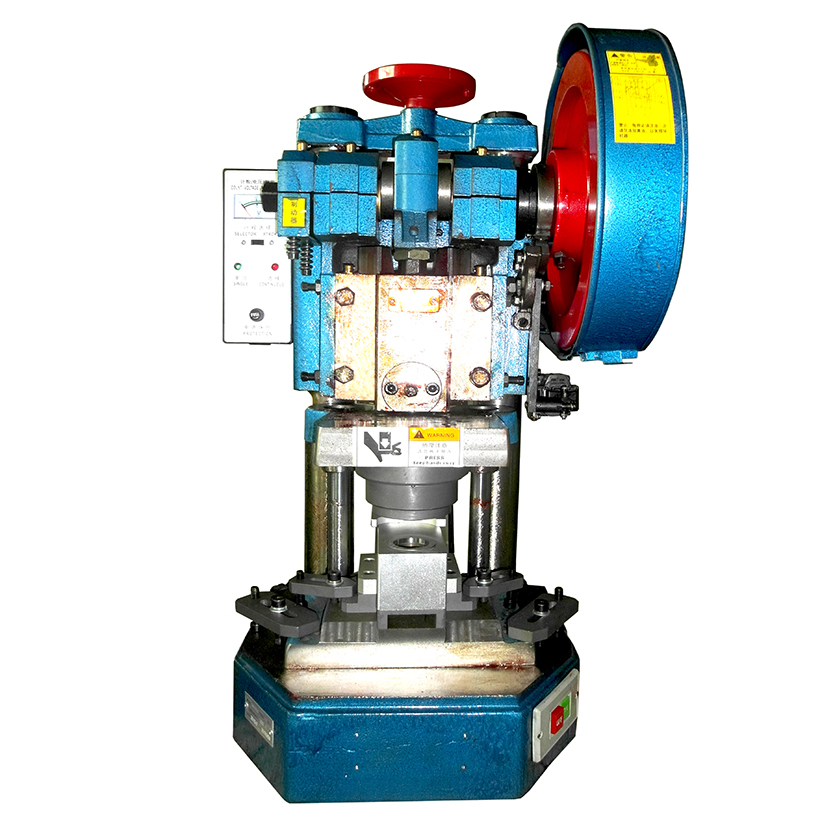

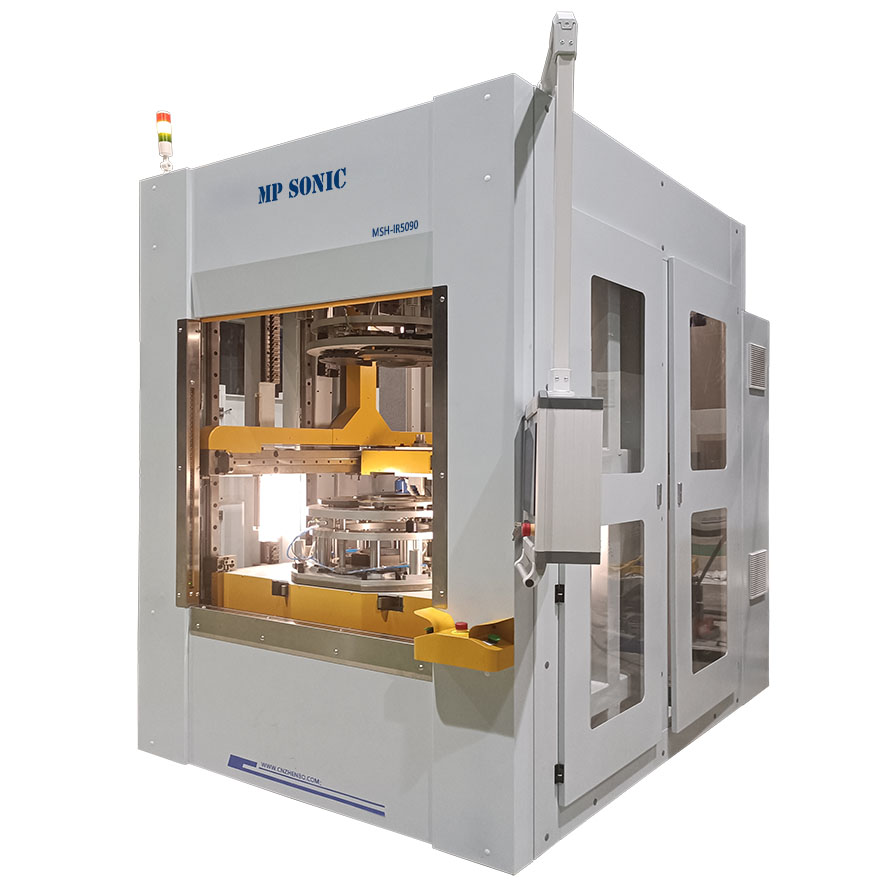

This line is a semi-automatic line designed to products cup-like N95 air-dust mask. For qualified N95 cup mask making, hot pressing forming macine, filter & PP Layer ultrasonic sealing machine and rotary table welding & cutting machine are essential. The other machines can be sleceted basing on mask design. Also it also can select a semi-automatic machine to finish the rest process after it processed by rotary table welding & cutting machine are essential.

Download: N95 Cup Mask Production Line

English

English