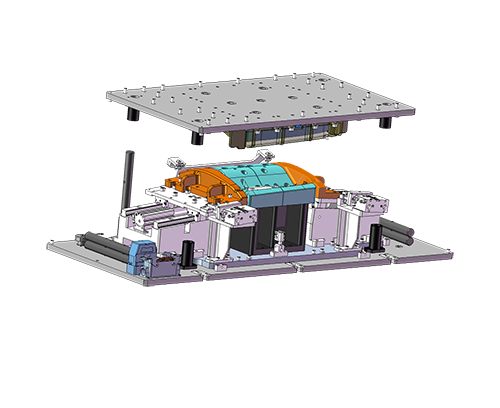

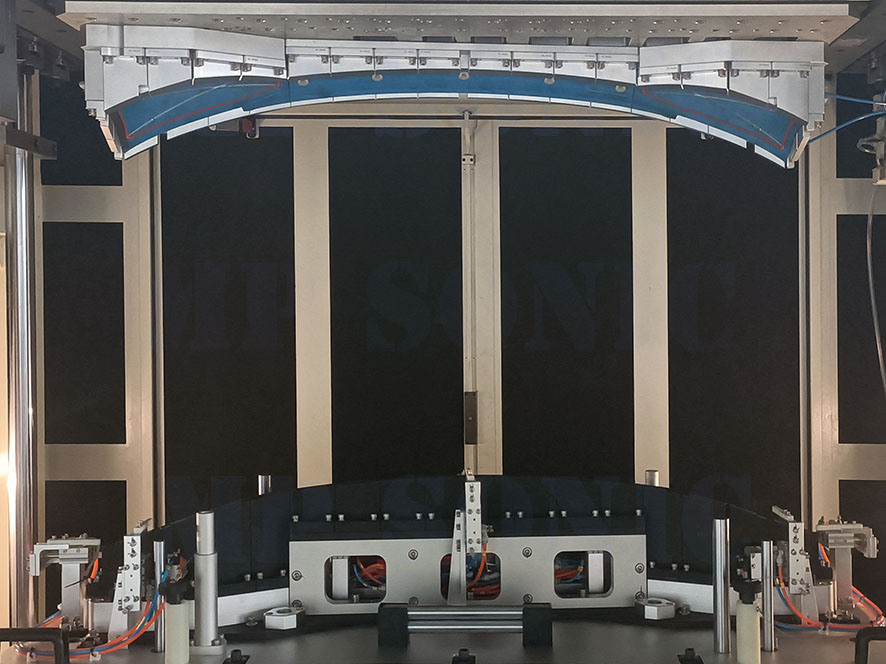

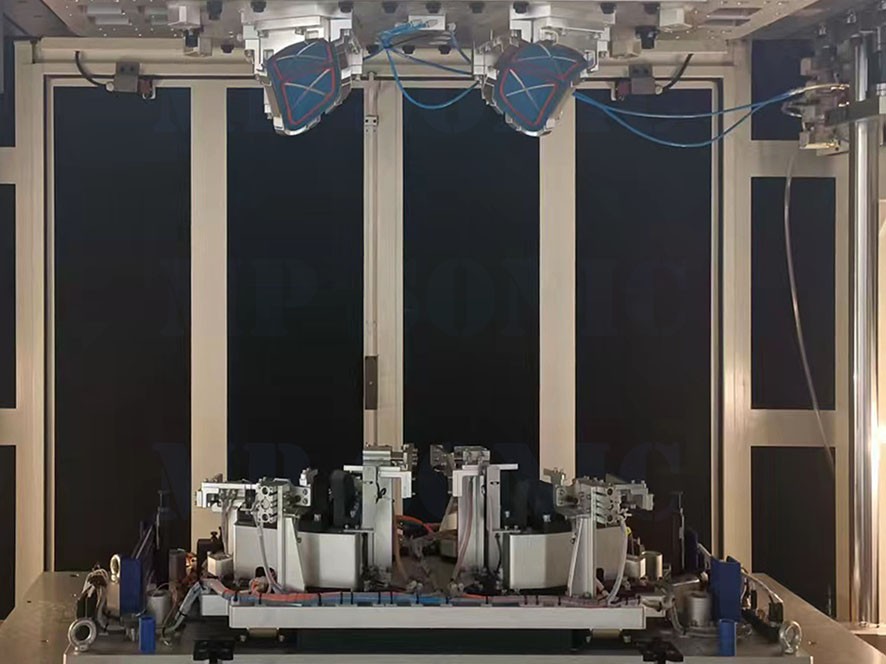

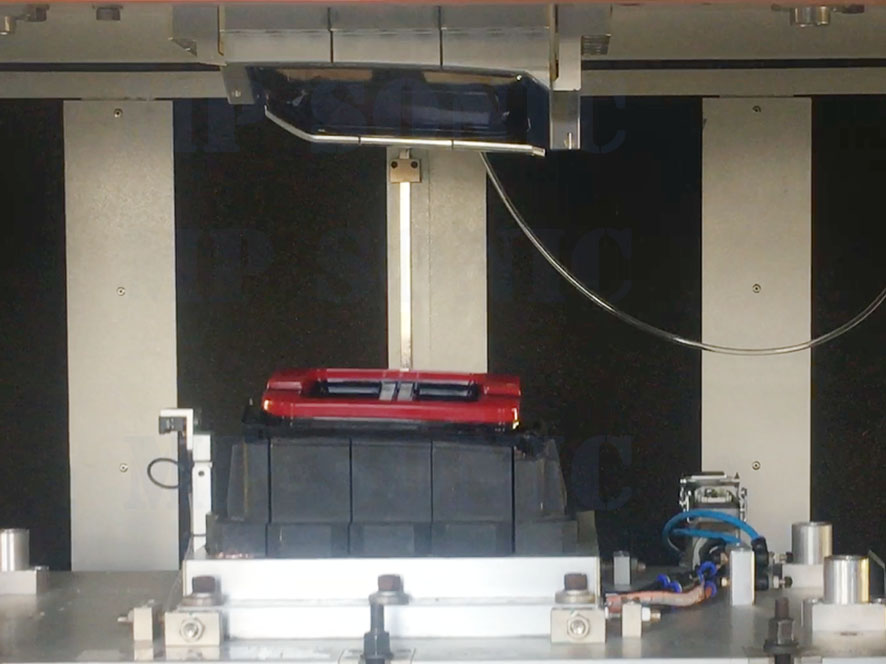

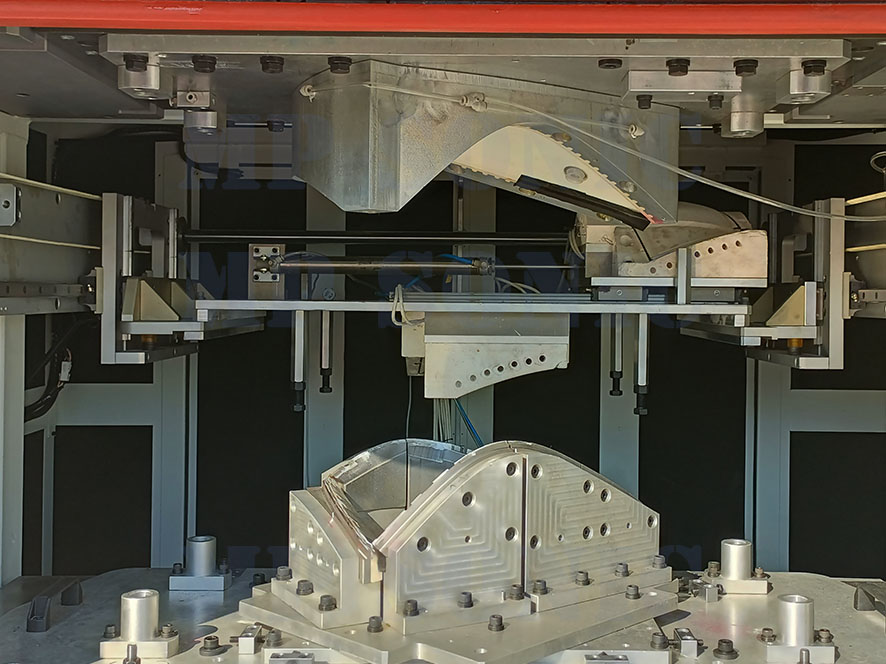

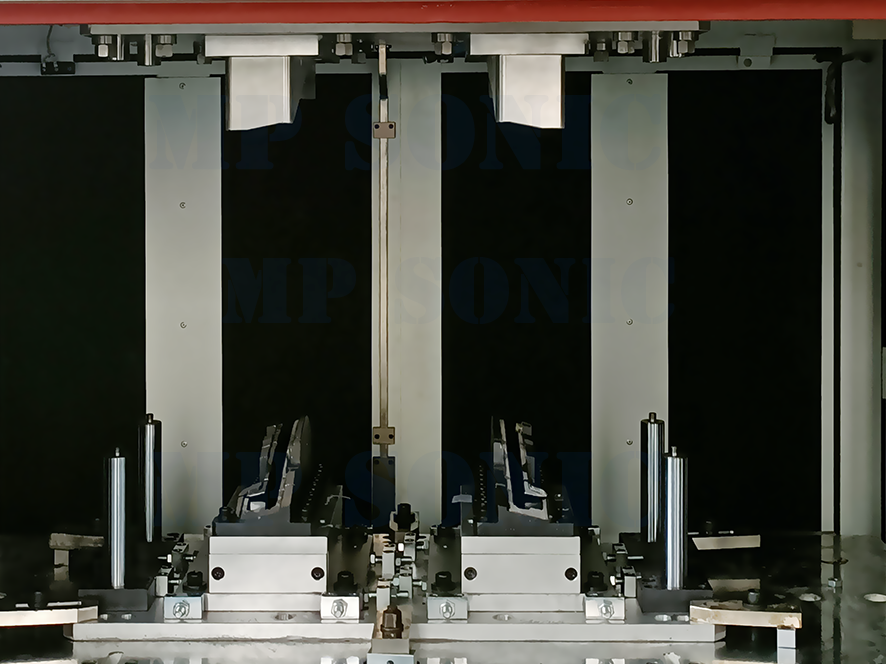

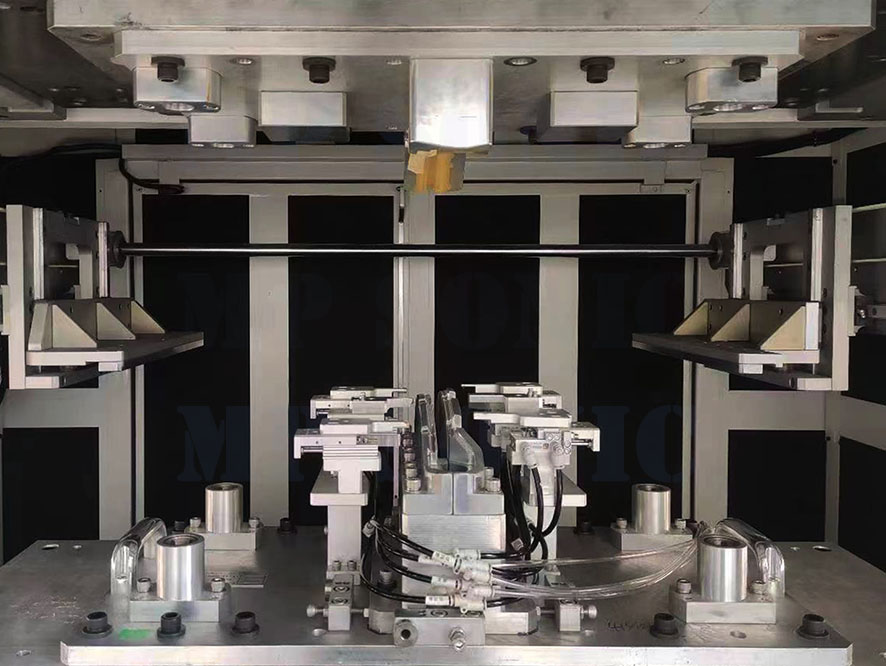

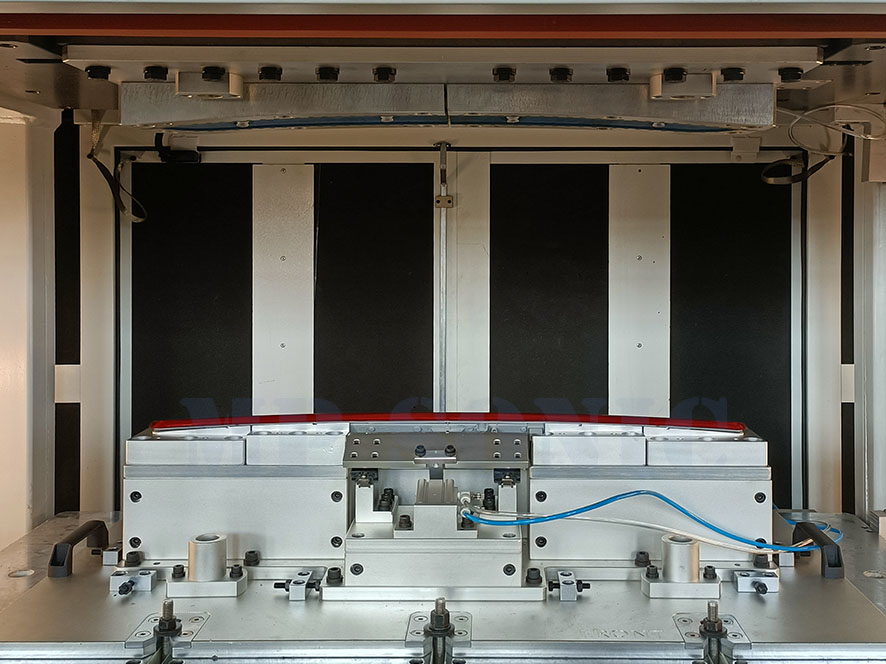

Vibration Welding Fixtures for Automotive Lighting

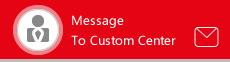

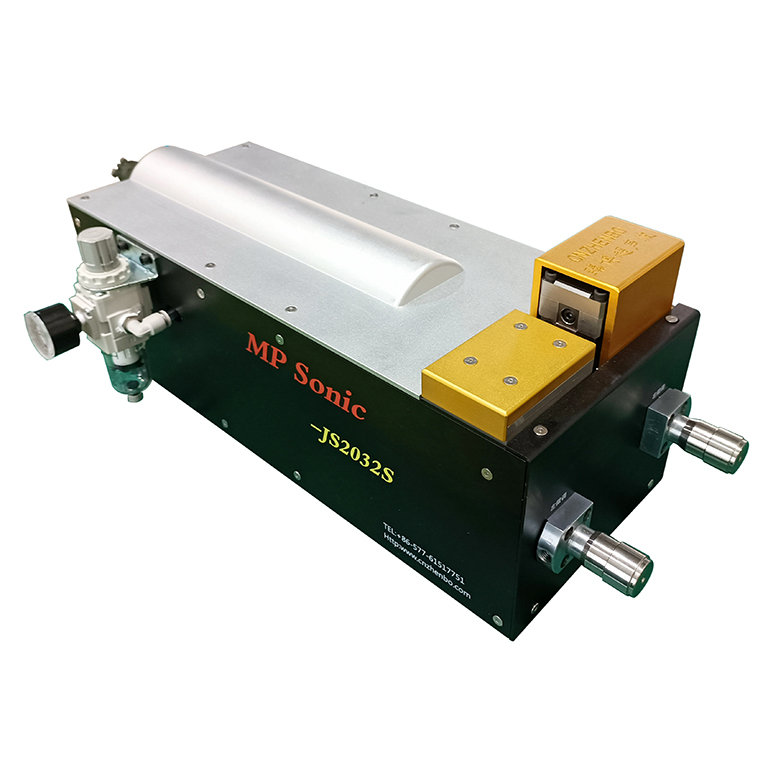

Linear vibration friction is welcomed by automotive lighting because of its advantages of flexibility of welding and reliable welding performance. MP Sonic designs and manufacturing vibration welding jigs mostly for tail lamp, fog light, HLBL (high level brake light), run-through type rear light, mirror indicator, side indicator, corner indication, reflector, etc.

Besides welding strength and air-tightness for its reliability, it requests highly in protection to light length and dust control in side of lamp, as well as the flexible & complex design of automotive lamp design, there is challenges of automotive lighting not only to welding machine system, but also to vibration welding tooling design.

English

English