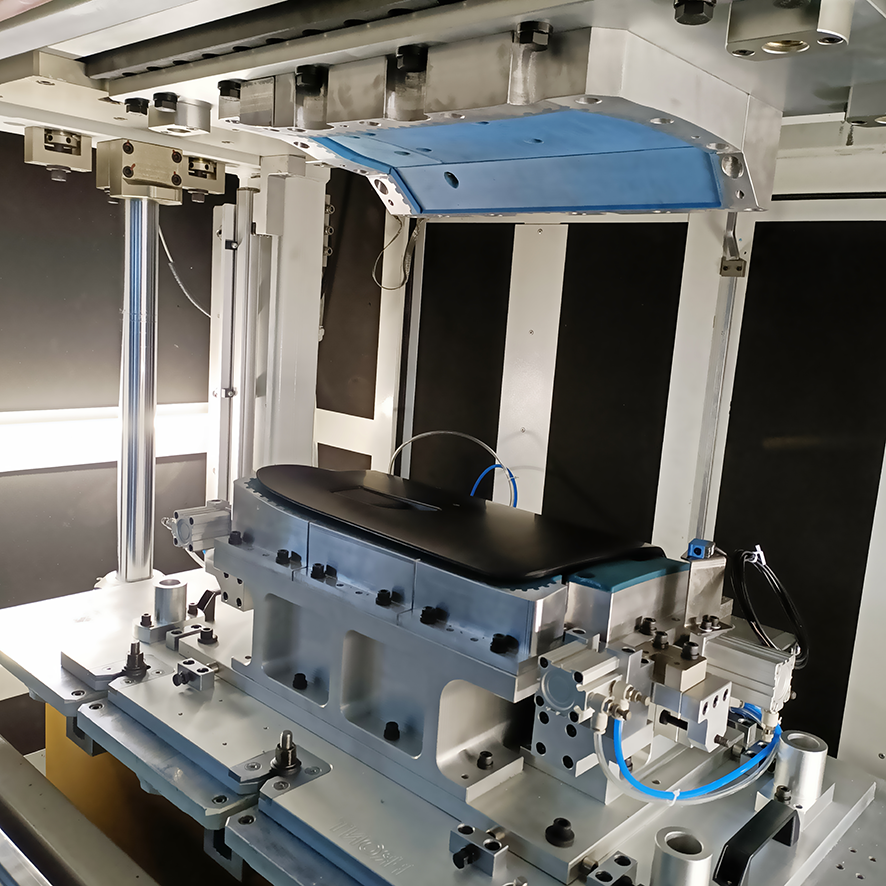

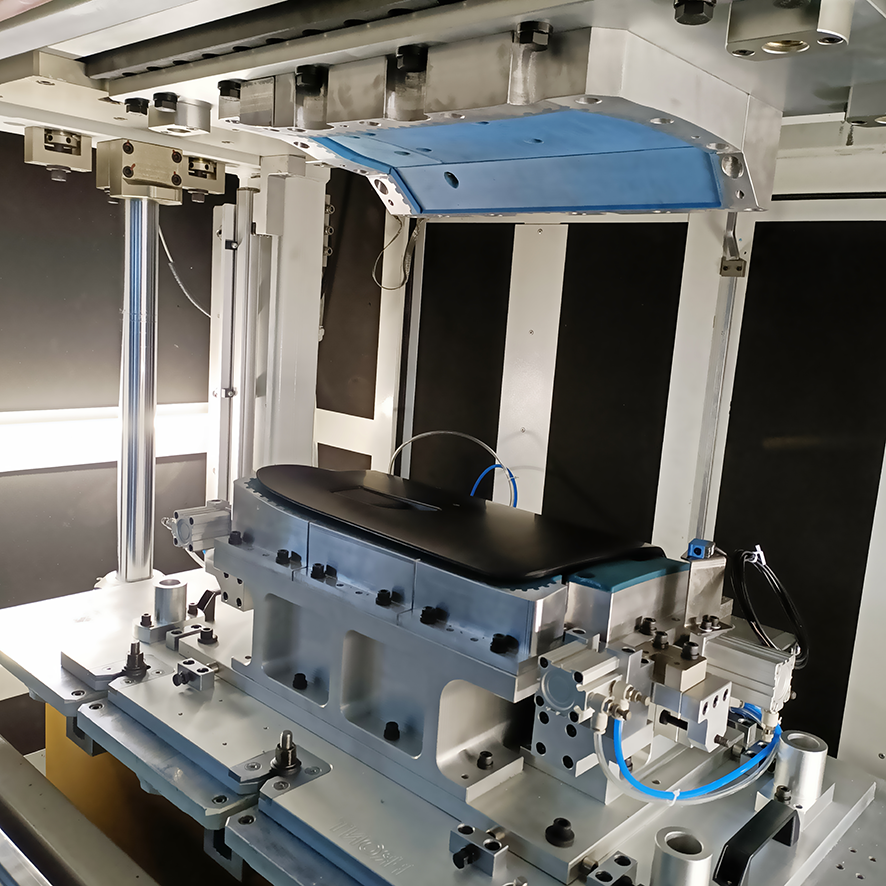

Glove box, means the drawer under dashboard panel, normally at passenger side, depends on glove box design, it requests to weld the exterior trim panel onto glove box or weld glove box lid panel separately.

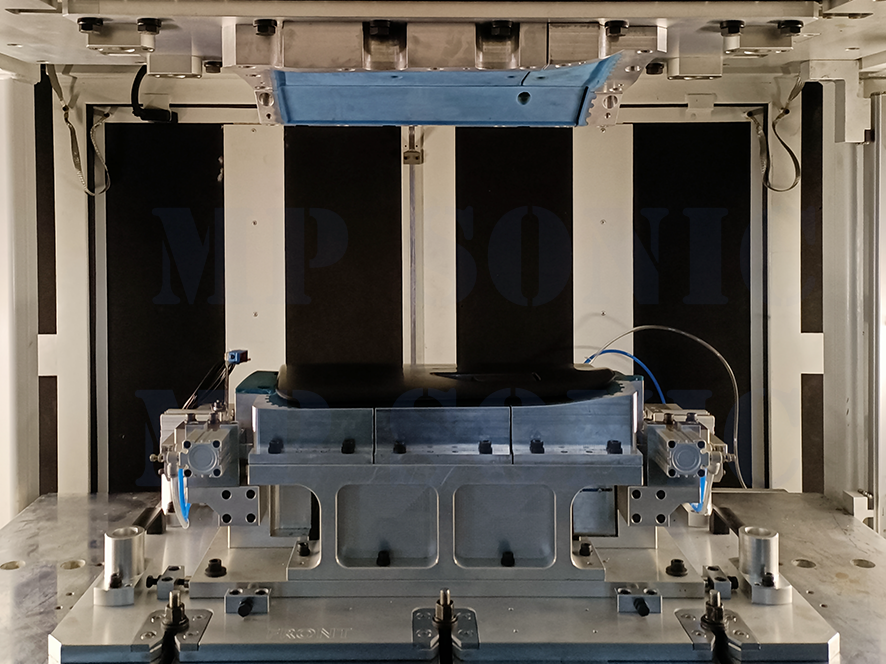

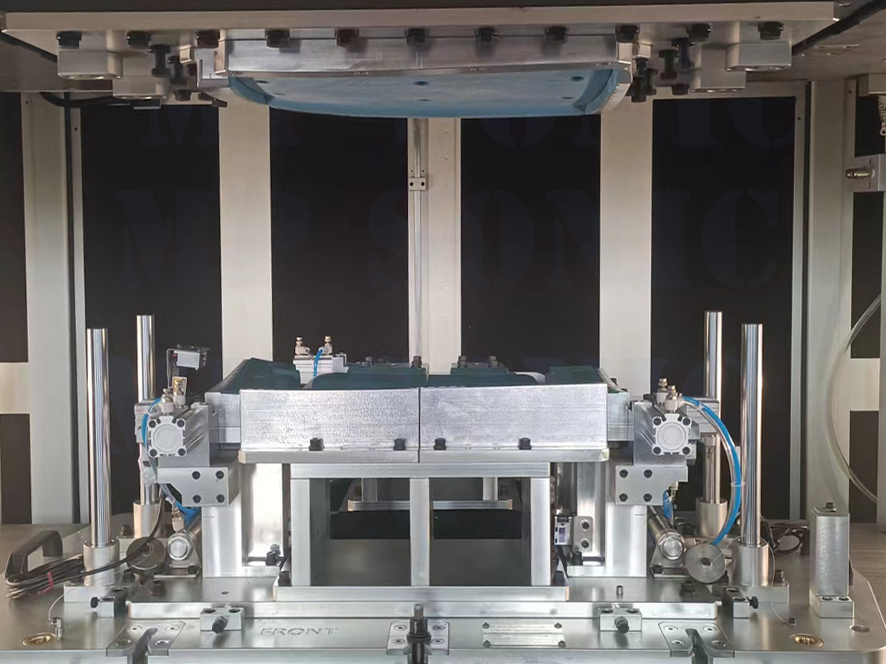

As a visible interior part, the exterior appearance of glove box and the measurement control is very important, thus the welding of glove box or glove box lid requests not only the strength, but also the protection of surface and the assembly precision. As well the complex of most glove box design, it requests strictly fixture structure design and material choice and process, and normally need to design some auxiliary function for realization of easy operation.

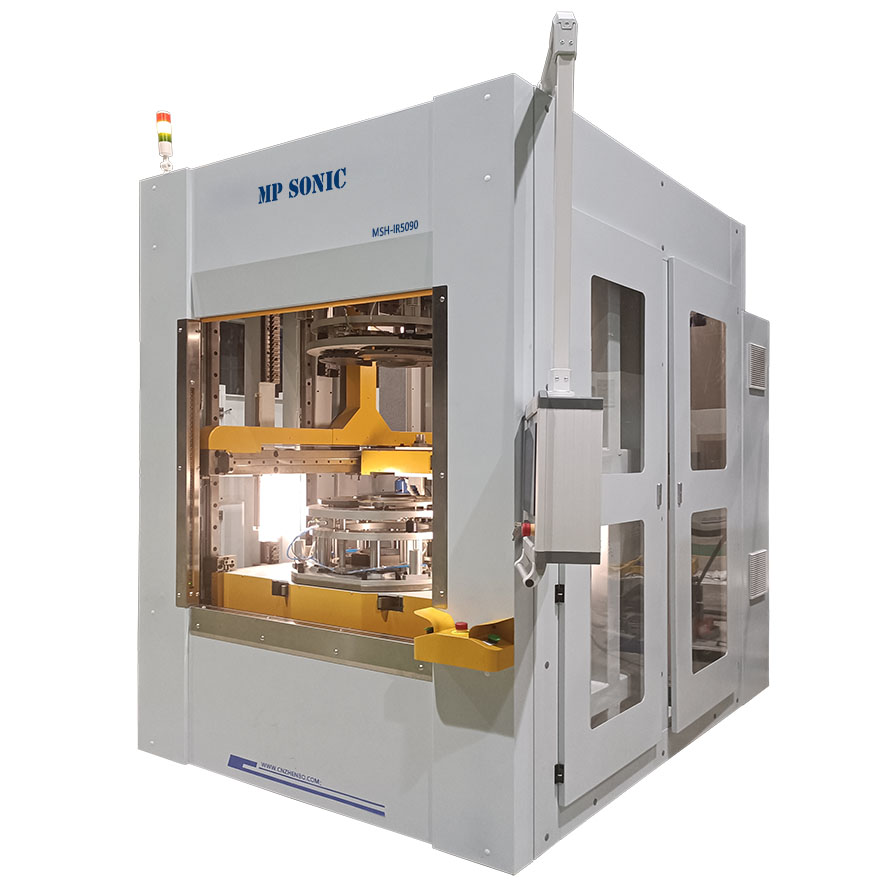

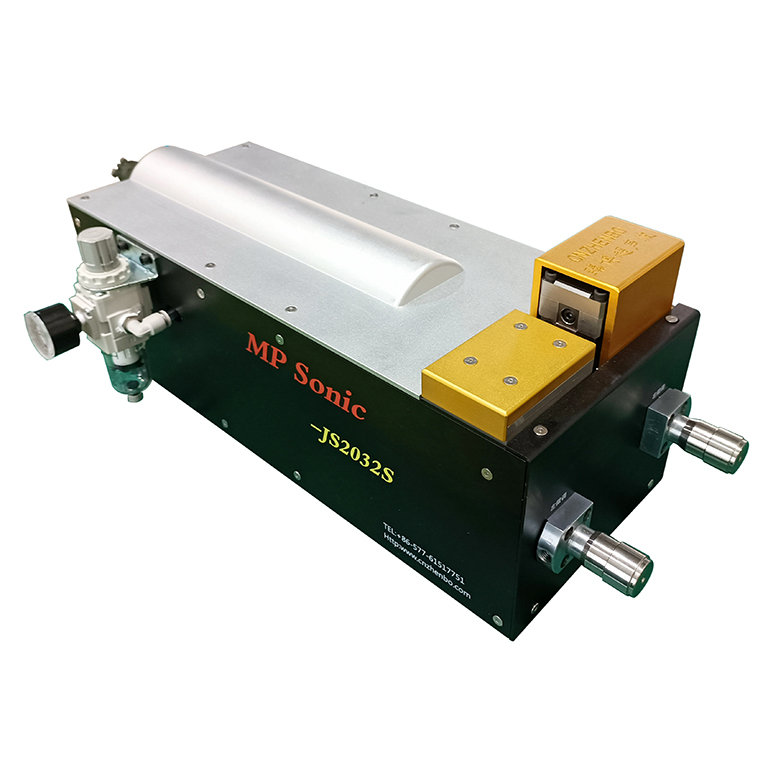

The welding of glove box normally with vibration welding machine in loading ability of 40KG or 70KG.

Read about MSV-650LS (40KG) or MSV-730LS (70KG).

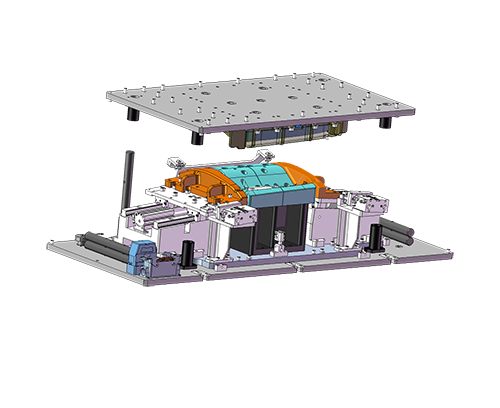

MP Sonic provide technical designing and manufacturing for glove box assembly welding tooling according to the detail requirement.

English

English