Technology Application in Garment Industry

by Alex Lee Email: alexlee2696@163.com Mobile/Wechat/WhatSapp: +86-15918523336

Cloths, trousers, shoes, caps, etc, are essential to every people in our lives. Now it is a fashion society, all people like beauty, beautiful garment takes up our eyesight mostly. But garment now is not only fashion, but also in functional features, protection against the cold, windproof, anti-UV, rainproof, etc. Various changing aesthetics and differential function requirement by clients , as well as the fast updated replacement in fashion styles and material, makes it can not meet the garment production demands by traditional procedure, especially besides seaming sewing arts and cold cutting is far from enough demand by garment production.

MP Sonic now provide garment production with seamless sewing technology and non-cold cutting arts, applying ultrasonic principle or others thermoplastic jointing principle.

Ultrasonic principles applied in garment industry included but not limited as below for examples:

I.Ultrasonic spot welding: applies ultrasonic spot welding to attached two cloths together or decoration to cloth.

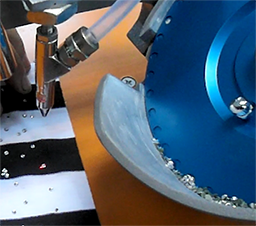

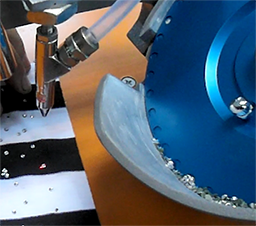

II.Ultrasonic spot seal: mostly it apply to seal decoration to cloth, shoes, caps, gloves, etc, especially such as plastic rhinestone as below image.

III.Ultrasonic sewing / Sealing: this is the most application of ultrasonic technique applied in garment production. It applies ultrasonic energy with rolling operation on cloth to form sewing or sealing by ultrasonic welding principle.

IV.Ultrasonic Lacing: it is apply ultrasonic system working with cutting roller performing on fabric to cut patterns and form decoration for garment. During cutting, ultrasonic energy will seal fabric fiber together at the cutting edge, forming sealed edge with no loose in neat and soft, which can not achieve by cold cutting or heating.

V.Ultrasonic roller cutting / bonding/Slotting: it is a extended application of ultrasonic lacing. Mostly applied to hold on cloth for pocket zipper.

VI.Ultrasonic knife cutting / punching: it is mostly applied to cut fabric is designed shape in sealed edge.

The most technique and equipment is applied by included by not limited as below:

I.Underwear / Underpants ultrasonic cutting & bonding

I.Underwear / Underpants ultrasonic cutting & bonding

II.Sport-wear ultrasonic sealing, cutting, bonding and vertical pressing welding

II.Sport-wear ultrasonic sealing, cutting, bonding and vertical pressing welding

III.Windbreaker / Winter Clothes, ultrasonic welding, cutting, slotting, etc

III.Windbreaker / Winter Clothes, ultrasonic welding, cutting, slotting, etc

IV.Insulation gown ultrasonic sewing / bonding (SMS)

IV.Insulation gown ultrasonic sewing / bonding (SMS)

V.Shoes vamp, insole / decoration ultrasonic welding / high-frequency welding

V.Shoes vamp, insole / decoration ultrasonic welding / high-frequency welding

VI.Garment Decoration ultrasonic welding, ultrasonic lacing, etc

VI.Garment Decoration ultrasonic welding, ultrasonic lacing, etc

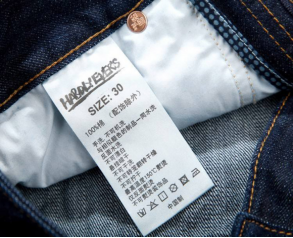

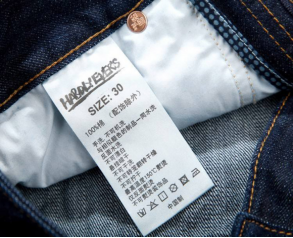

VII.Label ultrasonic cutting

VII.Label ultrasonic cutting

Note: the above images are downloaded from internet for illustration reference purpose only.

I.Underwear / Underpants ultrasonic cutting & bonding

I.Underwear / Underpants ultrasonic cutting & bonding II.Sport-wear ultrasonic sealing, cutting, bonding and vertical pressing welding

II.Sport-wear ultrasonic sealing, cutting, bonding and vertical pressing welding III.Windbreaker / Winter Clothes, ultrasonic welding, cutting, slotting, etc

III.Windbreaker / Winter Clothes, ultrasonic welding, cutting, slotting, etc IV.Insulation gown ultrasonic sewing / bonding (SMS)

IV.Insulation gown ultrasonic sewing / bonding (SMS) V.Shoes vamp, insole / decoration ultrasonic welding / high-frequency welding

V.Shoes vamp, insole / decoration ultrasonic welding / high-frequency welding VI.Garment Decoration ultrasonic welding, ultrasonic lacing, etc

VI.Garment Decoration ultrasonic welding, ultrasonic lacing, etc VII.Label ultrasonic cutting

VII.Label ultrasonic cutting