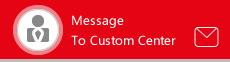

I.Standard Features:

1.Powerful servo control system in high precision, jig action speed is step control to achieve accurate hot platen welding control in divided phases;

2.Machine fast motion is especially good for low temperature hot platen welding;

3.Thermoplastic melting temperature is PID controlled, the welding temperature is controlled in stability and accuracy;

4.Error Heater ID is detected and indicated on screen for quick fault-shooting.

5.Formula feature system for parameters storage, when change-over hot plate welding tooling, it is easy to recall related welding parameter by select the relative parts ID;

6.Storage for welding record, alarm message record and fault record for future history check, helping factory SPC control;

7.Light fence at front operation window as well as safety doors at other sides equipped for human security all around;

8.Programmer auxiliary function of jigs to welding process including vacuum holding, slide block to base fixture, cylinder clamping, cylinder ejector, parts detection, etc;

9.Programmer welding process help achieve excellent hot plate or welding result.

II.Optional Feature:

1. Auto security at front door;

2. Auto jig loading system for quick tooling change-over;

3. Extra heating system for external preheating to hot platen;

4. Touch panel SPC;

5. E-tech module;

6. Auto electrical plugs and air connectors for welding tooling;

8. Automatic recognizing welding tooling to recall welding parameter automatically;

9. UPS;

10. Vacuum pump instead of vacuum generators;

11. External accessories detection to avoid welding unloading small parts;

12. GT I/O port to confirm parts loading location in precision.

III.Specification:

1.Power Supply: 380V 3P 50/60Hz;

2.Air Supply: 0.5Mp;

3.Overall Dimension:L1550*W2200*H2562 (mm);

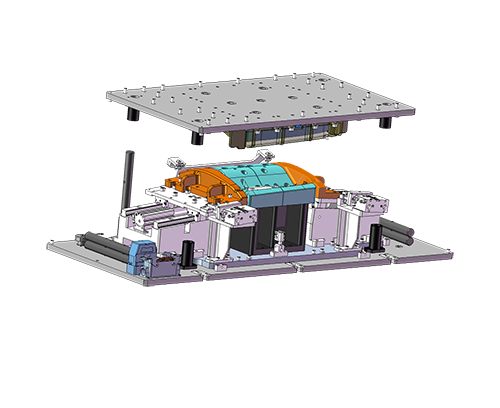

4.Jig Base Plates: 880*650 (mm);

5.Suggested Welding Square: =<750*600 (mm);

6.Max Welding Square: 800*600(mm);

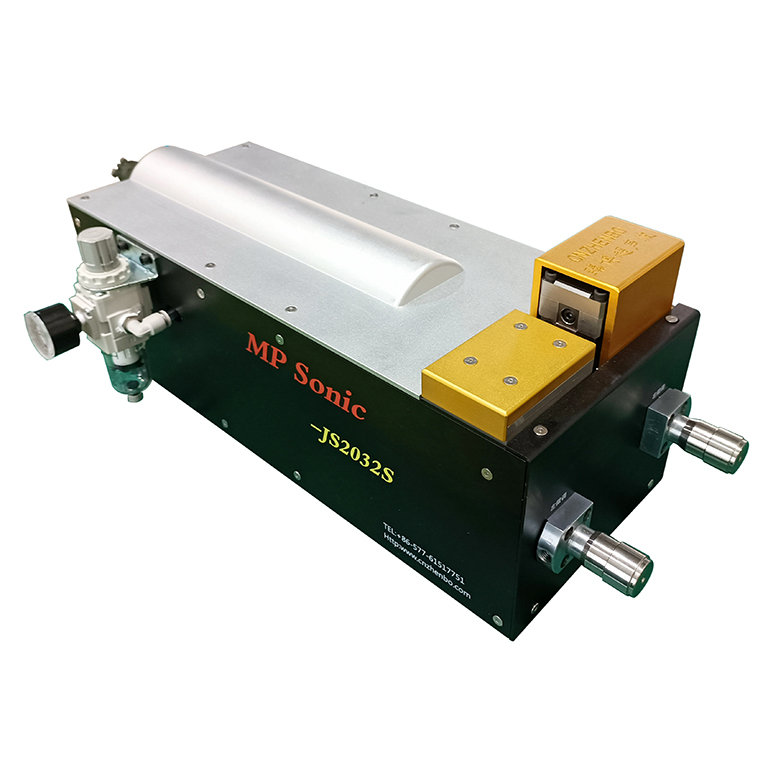

7.Jig Transmission: High Precision Screw Bar;

8.Hot Platen Transmission: Gear Bar;

9.Clips Number: 4+4;

10.I/o for Accessory Detector 6+6;

11.Cavity Parts Detector: 2+2;

12.Temperature Zone: 8 Sets.

English

English