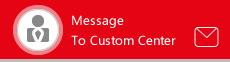

MP Sonic vibration welder normally applies specially designed servo hydraulic system to control lower jig bed and force welding in high pressure and motion precision. Machine elevating table motion distance is inspected by linear sensor to achieve close-loop control ensure high welding depth precision. Machine is applied for thermoplastic joining in challenge and high welding requirement. Especially is welcomed by automotive manufacturing, bathroom appliance manufacturing, etc.

I. Main Features:

1. Intelligent welding tooling loading system: A. automatic frequency tooling by one-touch-button operation; B. machine system search vibration starting height in automatic and load to welding parameter data by one-touch-operation.

2. Machine sequence PLC control and set on HMI. Programmable welding process meeting different welding requirement including parameters- vibration frequency, amplitude, pressure, welding depth, vibration time and fusing time, and tooling action-pneumatic parts motion & sensor detection, etc.

3. Dynamic graph displaying actual welding parameter output in time help supervise operation condition and ensure machine & welding performance.

4. Welding record automatically store in system memory quality management, including welding amplitude, time and force pressure.

5. Double welding mode for choice: timing mode & depth mode, meeting different operation requirement.

6. Welding process 8 stages control: welding parameters can be set separately to fit for different material characteristics.

7. Machine displays welding result judge once welding cycle finishes basing on actual welding parameters acts to help QC judgement.

8. Formula system: at least 80 sets of welding parameters storage help quick welding production shifting through formula recalling, no need to set tooling welding parameters again when it is loaded into machine the 2nd time.

9. Machine with multiple sensing detection, when any error, machine will make alarm, alarm message show on HMI helping trouble-shooting. Alarm history is kept in machine system and can be down load.

10. All related data concerned to welding operation can be down load by SD-card, USD or line-connect with computer.

11. Multiple safety production system, including automatic front door, optical fence for operation window, door safety sensor for rear door, multiple detection sensors as well as alarm system, protecting equipment and human safe all-round.

12. Multiple passwords protection for different operation/technology with different levels of authority, achieving complete production management purpose.

13. Machine system has prepared program for cam sliding function of tooling for parts welding in complex geometric shape design.

14. Machine system automatic check upper jig center and balance to escape vibration operation in error condition, ensuring equipment safety and welding result.

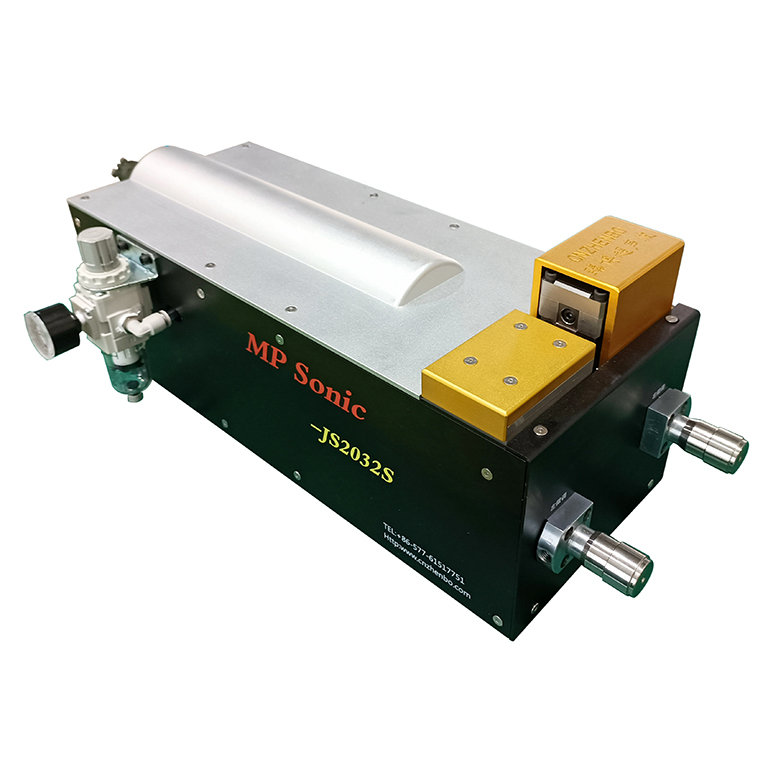

15. Lifting table elevating and clamp force is controlled by MP Sonic specially designed servo hydraulic system, ensuring performance stability and motion accuracy in speed and depth, and pump is working only when table is descending or ascending, reducing power consumption. Our designed hydraulic generates much lower sound comparing others brand machine, lowering noise to working environment.

16. Machine elevating table motion is closed-loop controlled, ensuring precision welding depth.

17. Machine noise is under 80db, no harm to human, meeting international standard.

18. Machine design with function of vacuum generator and extra solenoid valves for different tooling action design requirement.

19. Machine designed with super-self-inspection to check machine vibration system parameter and hydraulic system parameters to ensure machine normal working performance and machine safety (requests super-password);

20. 4sets of I/O points spare for tooling applied sensors to detect parts presentation or location.

21. E-tech communication for machine.

22. Wifi module with i-cloud system for remote service, realize quick machine maintenance and problem-shooting in economical cost.

23. Printer port.

24. Operation system multi-language including Chinese, English, Italian, Russian & Korean.

II. Optional Features:

1. Lifting table pure electrical servo motor control

2. IR-preheating system (CVT).

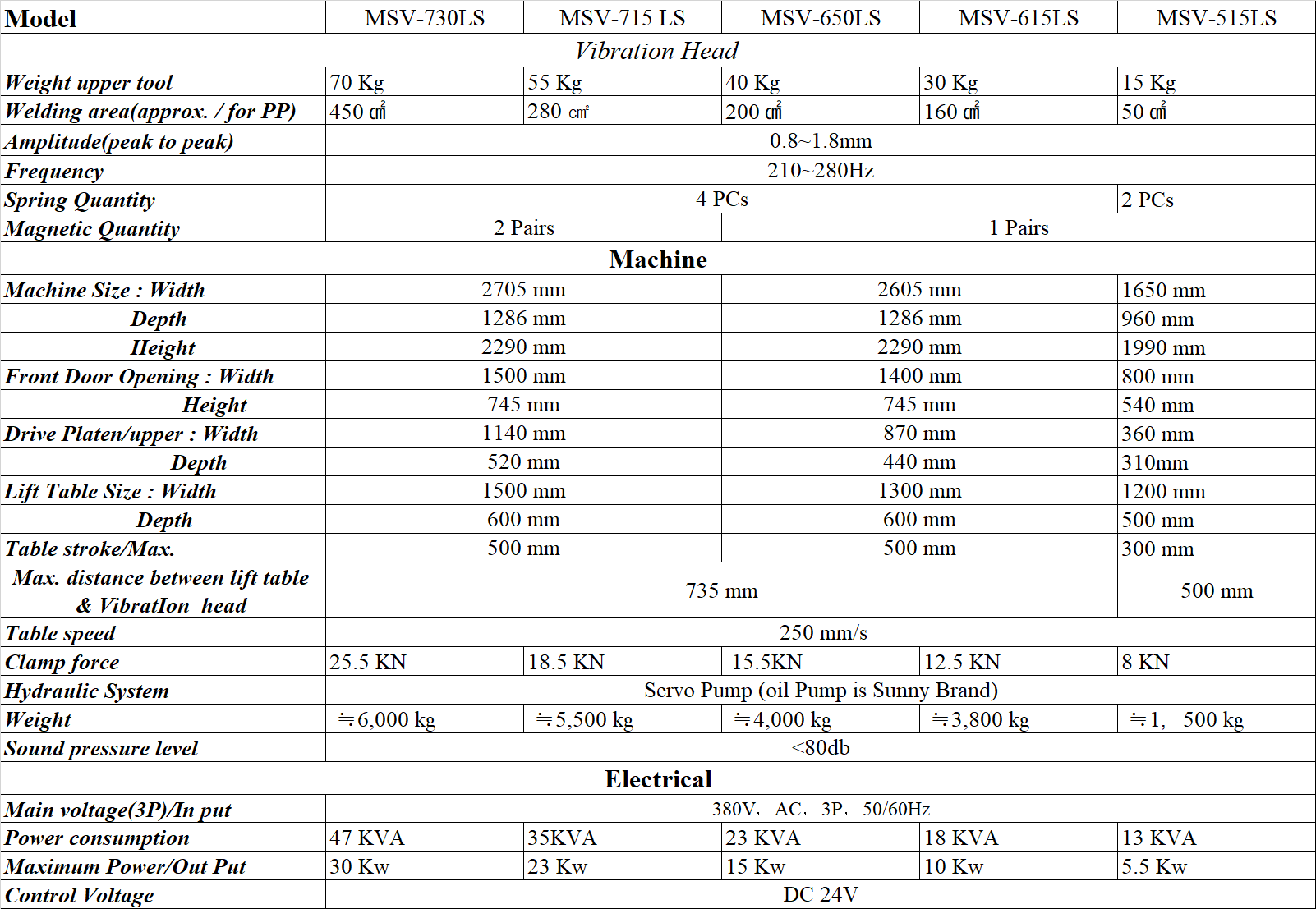

III. Specification Sheet:

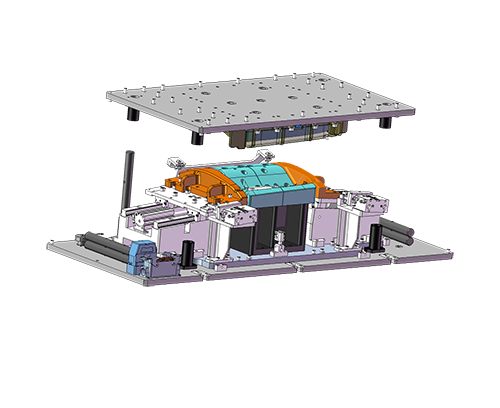

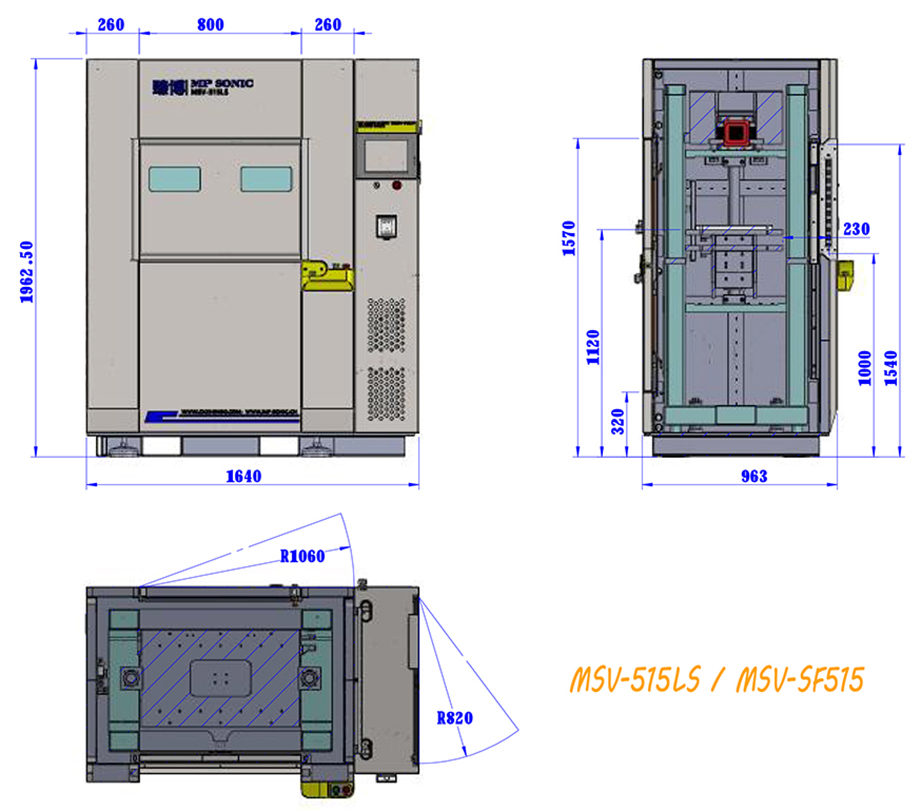

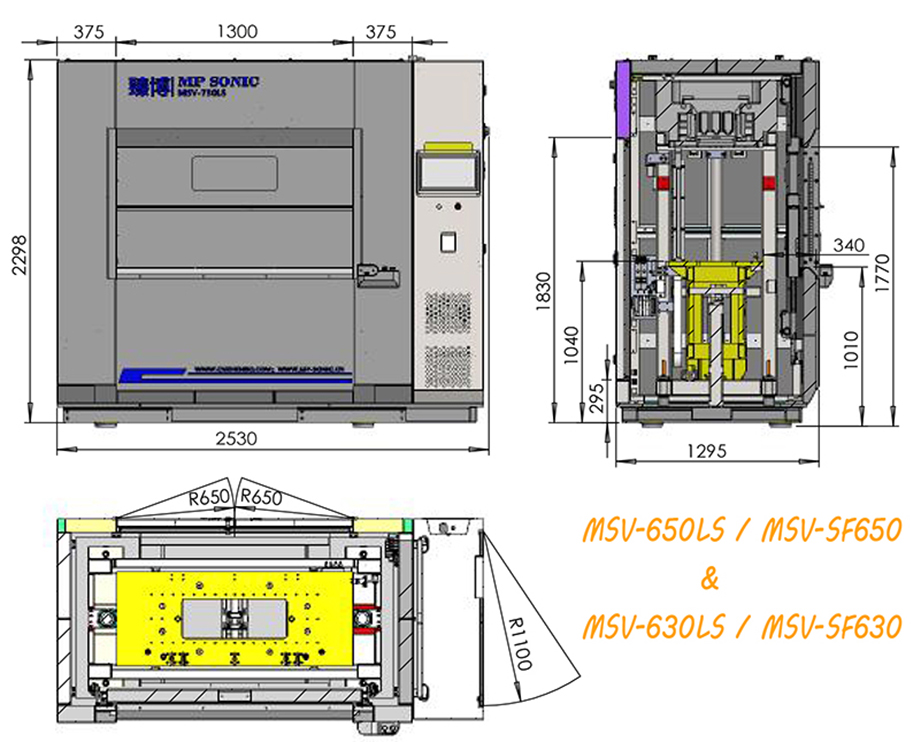

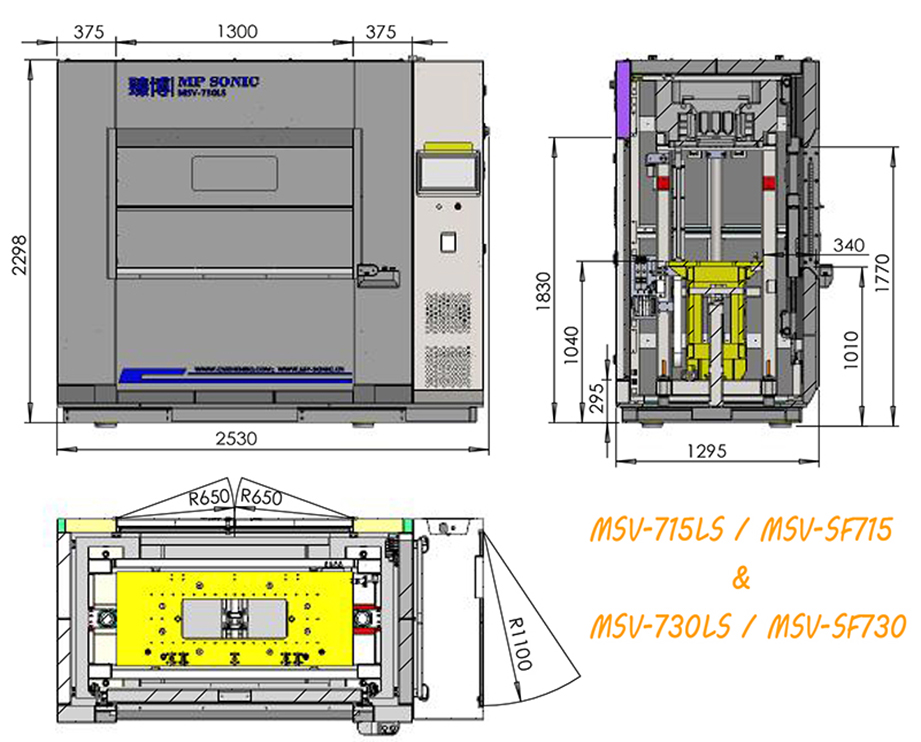

IV. Machine Measurement Layout.

English

English