How is about Ultrasonic Metal Welding

by Alex Lee; Email: alexlee2696@163.com; Mobile/Wechat/WhatsApp: +86-15918523336

Ultrasonic welding is applied the mechanical energy of ultrasonic wave (normally over than 18KHz) to joint two objects in same or different material, such as metal material, semiconductor material, plastic material, ceramic, etc.

Ultrasonic metal welding technology is fast, clean & economical, which is applied in various industrial area.

Ultrasonic welding procedure is a process between cold welding and friction welding. It uses high-density energy generated by oscillation in high frequency. By this welding procedure, the oscillation direction of horn for ultrasonic metal welding will be parallel with work-pieces. During welding operating, the static pressure acts perpendicularly on the welding surface through the welding head, and the shearing force of the high-frequency vibration is superimposed at the same time. When the shears force exceeds the elastic limit of the material, the park of the work-piece contacting surface begins to slip. This shearing force in the welding process, the direction of the tens of thousands of times per second is continuously changed. The surface of the work-piece is cleared .The surface of the pure metal begins to contact in multiple points. With the continuation of the high-frequency vibration, the contact area of pure metal continues to expand. Until it expands into the entire weld zone, at the same time atomic diffusion takes place at the contact surface, and metal re-crystallization produces a fine-grained micro-structure and exhibits cold deformation characteristics of the metal.

Ultrasonic welding procedure is a process between cold welding and friction welding. It uses high-density energy generated by oscillation in high frequency. By this welding procedure, the oscillation direction of horn for ultrasonic metal welding will be parallel with work-pieces. During welding operating, the static pressure acts perpendicularly on the welding surface through the welding head, and the shearing force of the high-frequency vibration is superimposed at the same time. When the shears force exceeds the elastic limit of the material, the park of the work-piece contacting surface begins to slip. This shearing force in the welding process, the direction of the tens of thousands of times per second is continuously changed. The surface of the work-piece is cleared .The surface of the pure metal begins to contact in multiple points. With the continuation of the high-frequency vibration, the contact area of pure metal continues to expand. Until it expands into the entire weld zone, at the same time atomic diffusion takes place at the contact surface, and metal re-crystallization produces a fine-grained micro-structure and exhibits cold deformation characteristics of the metal.

I. Types of Ultrasonic Metal Welding

Normally, the ultrasonic frequency for ultrasonic welding includes: High-frequency (50Khz or over than 50KHz), intermediate-frequency (30~40KHz), low-frequency (20KHz). Higher is the frequency, lower is the power capacity and thinner is the welding, thus, normally the ultrasonic metal welding means in intermediate-frequency and low-frequency.

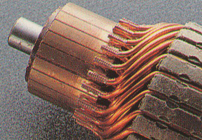

1. Spot Welding

1. Spot Welding

Oscillation system for spot welding can be divided into longtitudinal oscillation system, bending oscillation system and torsional oscillation system, according the wave pole oscillation condition. Normally, the torsional oscillation is applied for ring welding. Most metal spot welding applies lingtitudinal oscillation.

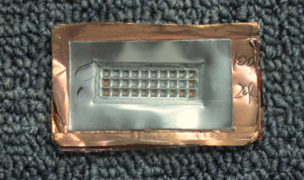

2. Rolling Welding

2. Rolling Welding

Rolling welding generally applies bending oscillation system. The diameter of welding pad will fix the wave length.

The most application of rolling welding to metal by ultrasonic: solar cell, flat solar panel, aluminum-plastic composite tube, copper panel, aluminum panel, etc.

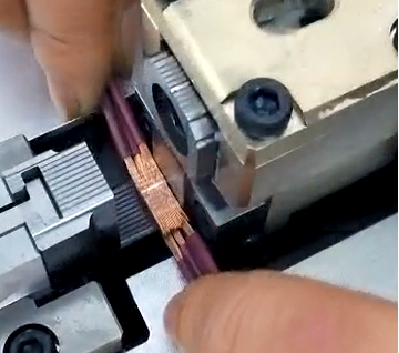

3. Harness Welding:

3. Harness Welding:

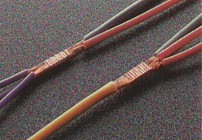

Presently, it is applied for: wire harness for automotive, wire terminal moulding, wire mutual welding, multiple wire welding together into wire lug, copper wire and aluminum wire conversion, etc.

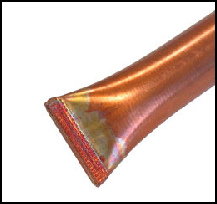

4. Cutting & Sealing

4. Cutting & Sealing

Ultrasonic cutting & sealing machine mostly used for: refrigerators and air-conditioner; cutting & sealing vacuum parts made of copper or aluminum.

II. Application of Ultrasonic Metal Welding:

II. Application of Ultrasonic Metal Welding:

welding on multiple-layers positive and negative electrodes of NiMH battery, welding between nickel mesh and nickel sheet of nickel battery;

2. Welding Copper foil and nickel sheet for lithium battery of polymer battery; welding between aluminum foil and aluminum sheet, or aluminum sheet and nickel sheet;

3. Wires used on automotive, wire terminal moulding, wire mutual welding, multiple wire welding together into wire terminals, copper wire and aluminum wire conversion, etc;

4. Welding between wire and electronics, connection terminal, connectors, etc;

5. solar cell, flat solar panel, aluminum-plastic composite tube, copper panel, aluminum panel, etc.;

6. High current connection welding, contacting points welding, dissimilar metal welding, etc, for solenoid switch, fuse-less switches, etc;

refrigerators and air-conditioner; cutting & sealing vacuum parts made of copper or aluminum.

III. Advantages of Metal Welding by Ultrasonic

III. Advantages of Metal Welding by Ultrasonic

1. For metal properties as non-melting and non-weaking

2. Excellent electrical & thermal conductivity after welding, the electrical resistivity value is very low almost to 0.

3. Low requirement to the welding surface of metal parts, the welding is available to oxidized or plating parts;

4. Fast welding, no need any flux, gas or solder;

5. Easy achieve the welding between different metal material;

6. Easy realize automation control;

7. The welding doesn't generate spark, operation is fast and safe.

View Ultrasonic Metal Welding Machine