Joint Design for Vibration Welding

by Alex Lee of MP Sonic

Mob/Wechat/WhatsApp: +86-15918523336

Email: alex.lee@mp-sonic.com; alexlee2696@163.com

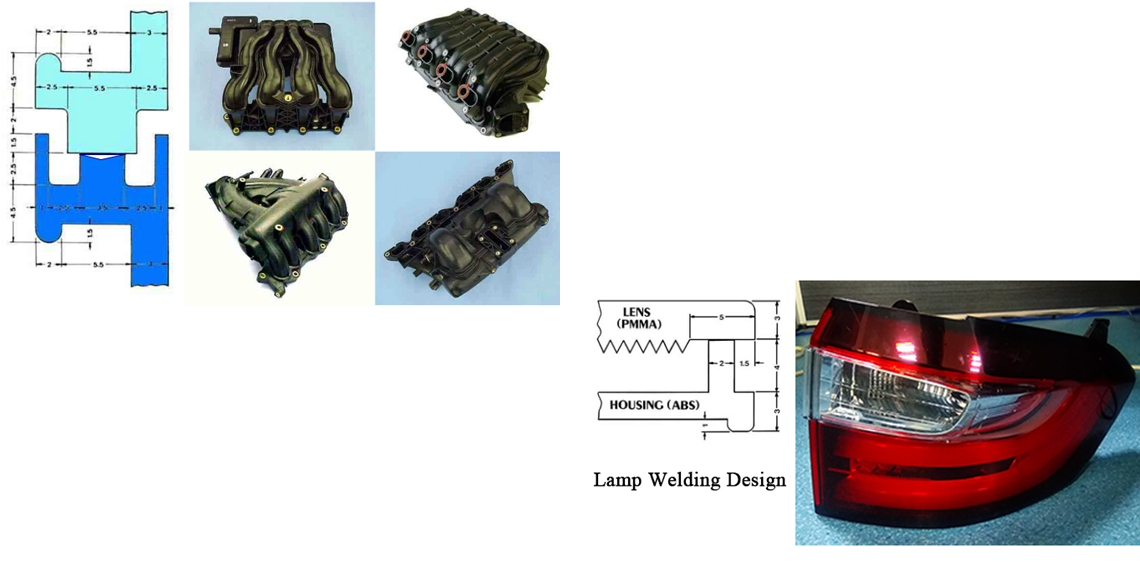

Join design for vibration welding concept:

1. Measurement of welding rib;

9. Ensure that the surface slope at vibration direction no over than 10 degree.

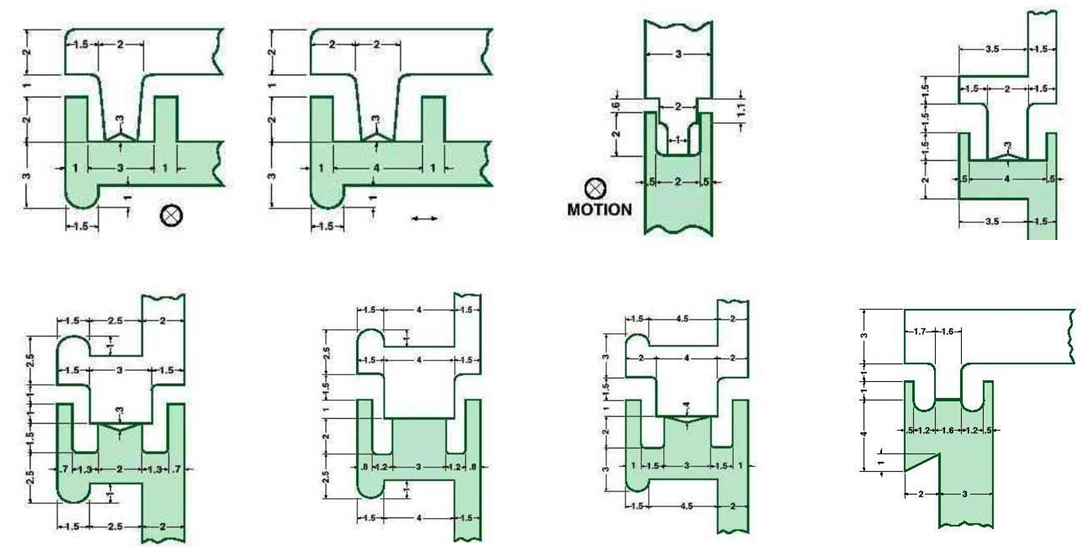

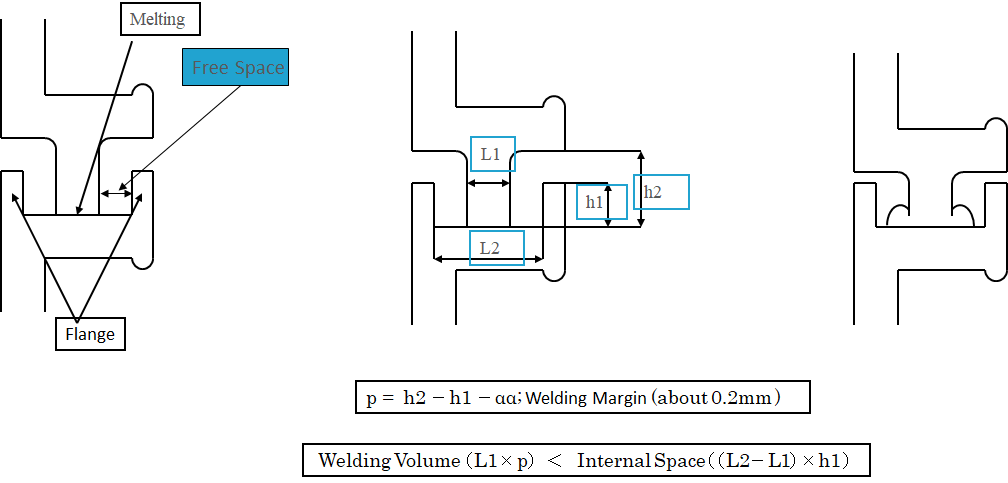

I. Welding Design Measurement

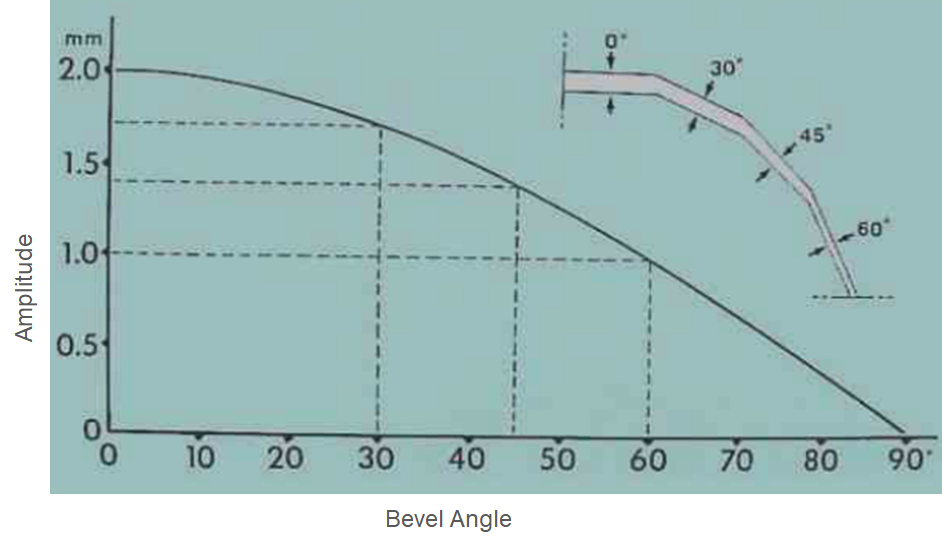

II. Bevel Angle of Welding Surface

III. Welding Design Construction

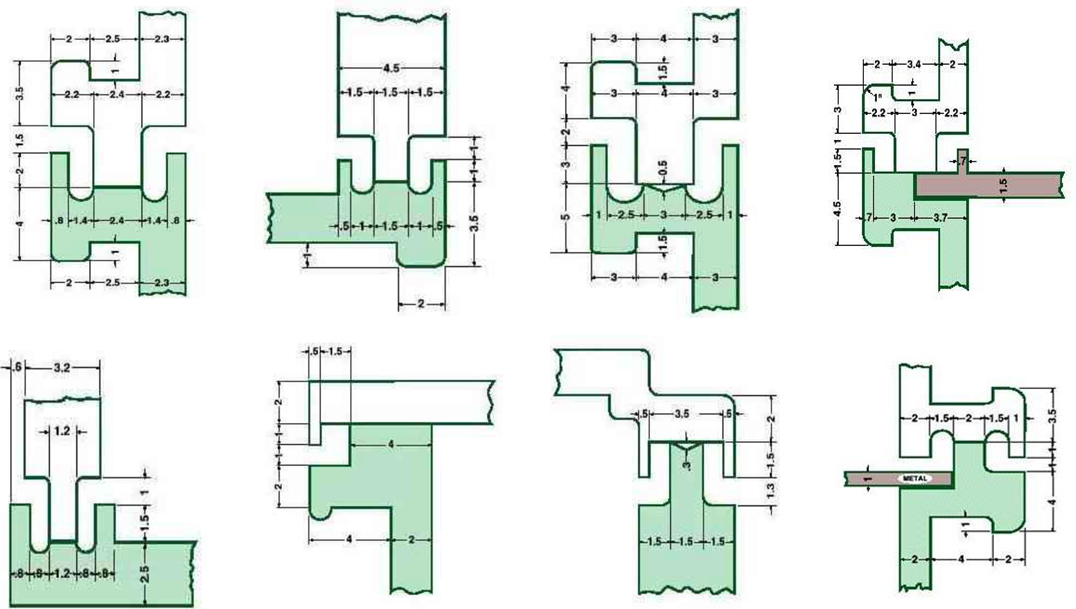

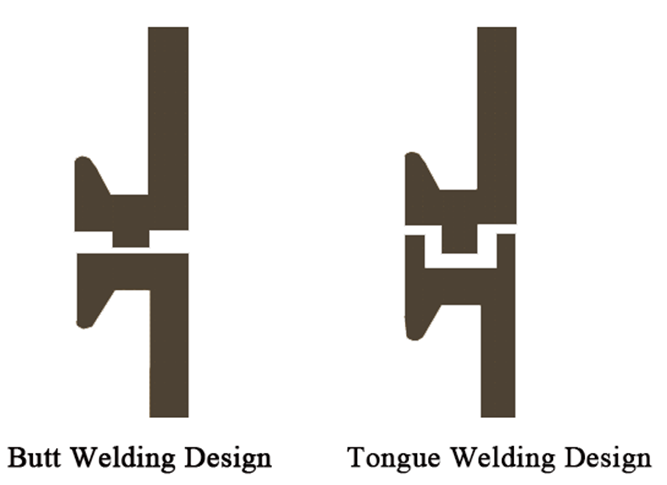

IV. Types of Welding Design

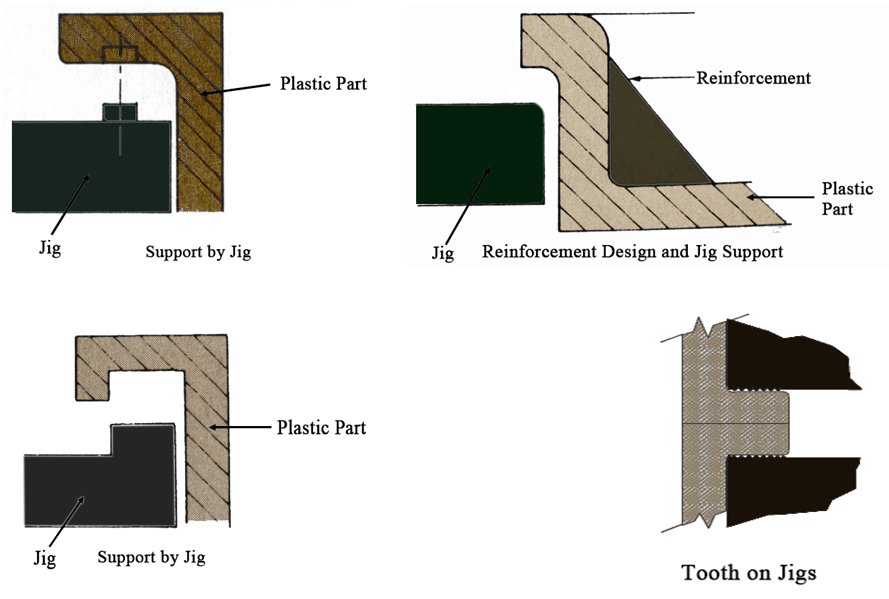

V. Support Design for Vibrtion Welding

VI. Usually Applied Joint Design for Vibration Welding