Rotary Table Sealing & Cutting Machine for N95 Cup-like Mask

Rotary Table Sealing & Cutting Machine for N95 Cup-like Mask

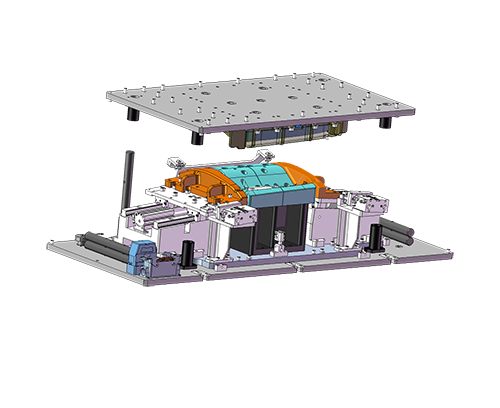

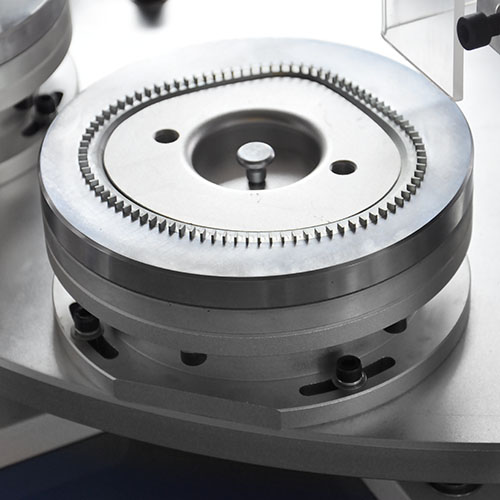

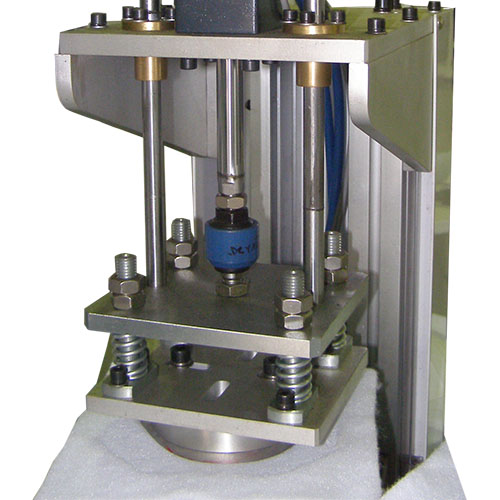

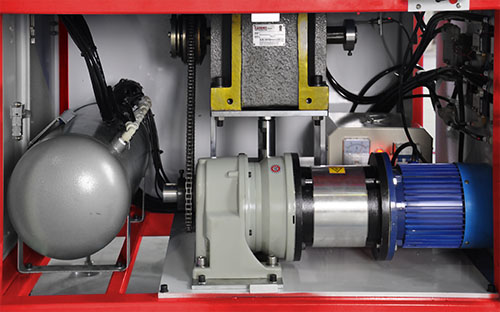

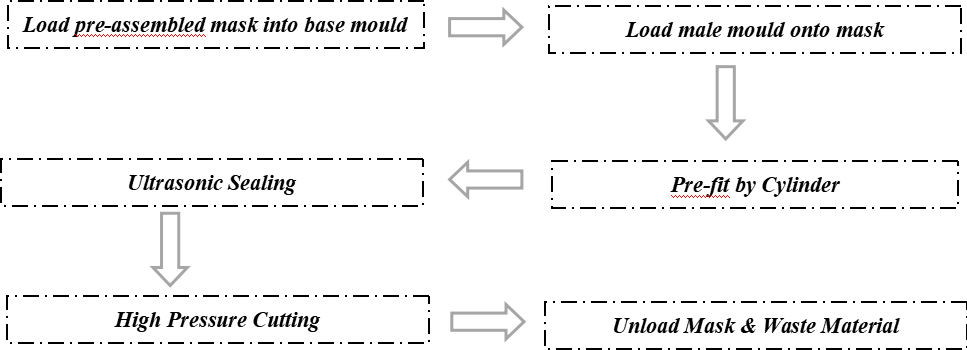

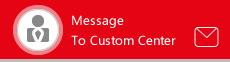

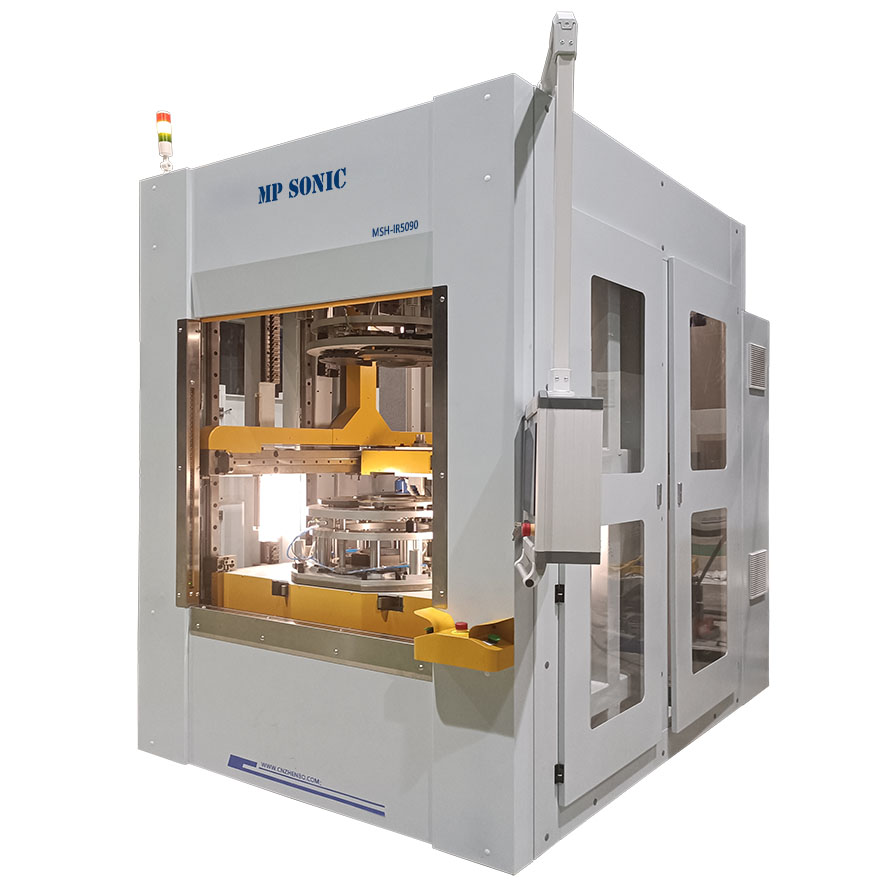

IBN-CM320 is a semi-automatic machine designed to seal different fabric layers together and cut off waster material around mask. Machine is 4 process-stations design, it indexes between stations by rotary table in precision. Machine seal needle punching layers together with filtration layers and PP layers together by 15KHz ultrasonic system in power output 4200W. Before ultrasonic cutting, pre-fitting to mask layers is forced by cylinder pressing to ensure mask layers in good fitting manner. After ultrasonic welding, high pressure cold cutting module is applied to cut off waster material to get neat edge. Optical sensor detects mask before action, if there is no mask loaded into any base mould, process module will not activate when the related base mould reach the related station.

IBN-CM 320 rotary table sealing & cutting machine is essential for the production of cup-like mask in N95 or higher standard.

English

English