Introduction about Ultrasonic

By Alex Lee, Email: alexlee2696@163.com, Mobile/Wechate/Whatsapp: +86-15918523336

I. What is ultrasonic?

Ultrasonic means the sound wave whose frequency is over than the audible sound frequency to human. To human, the audible frequency of sound normally from 16KHz to 20KHz, thus the sound wave in frequency over than 20KHz is called as ultrasonic (or be called as ultrasound). But human hearing sensitive is much lower than most of other human, and most animals is sensitive to sound in frequency over than 20KHz, eg, a cat can hear sound in about 64KHz. And it is reported by “Biology Report”on internet that most kinds of moth can hear sound in frequency as high as 300KHz, then it says that moth ear is the most sensitive in the word. Presently, so far as we know that the frequency of sound from a bat mouth is about 212KHz,which is more than ten times of that human can hear. The frequency of sound wave made by bat is in range of ultrasound.

The sound normally is divided into infra sound, audible sound, ultrasound, microwave sound and optical wave sound, and the related wave frequency can refer as below image.

But normally, because of the application of sound wave in the daily industrial production can be as low as 15KHz or lower which is also audible to human, especially for the welding application area, we call welding machine in 15KHz frequency as ultrasonic welding machine or ultrasonic welder.

II. The application of ultrasonic principle?

Ultrasound can be wide applied in various area: such as in military field, civil appliance field, industry production, etc. Eg, it can be applied to sonar detection, ultrasonic steel inspection, driving animals, ultrasonic washing, ultrasonic plastic welding, ultrasonic metal welding, ultrasonic emulsification, ultrasonic cutting, ultrasonic boring,ultrasonic polishing.

The mostly applied ultrasonic in industries is ultrasonic plastic welding, ultrasonic metal welding, ultrasonic cutting, ultrasonic cleaning, ultrasonic sewing / bonding, etc.

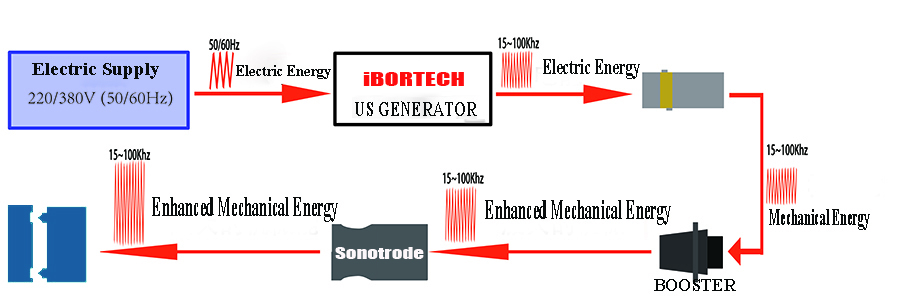

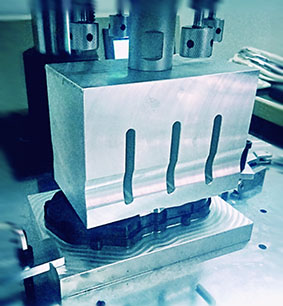

II-1. Ultrasonic welding, including ultrasonic plastic welding & metal, means applied a ultrasonic generator which is as a power supply of ultrasonic system to convert supplied electric in low frequency, such as 220V or 380V, to the ultrasonic frequency, normally 15KHz to 70KHz, and supplies to ultrasonic transducer which also called as converter, by which the electrical energy is transfer into mechanism oscillation energy to work on work-pieces and case the internal oscillation and friction between molecules of material to generate heat and melt material, by which the molten material at the contacting area infiltrate into each other and stick together to form welding. Here, please be note that normally we do not finish through working transducer directly to work-pieces, because the wave from transducer is very short whose oscillation power is not enough to melt material, but it requests booster and horn (also called as sonotrode) to enhance the wave amplitude and work on work-pieces by a ultrasonic horn. It can be clearly explained by below image.

Ultrasonic welding is with the advantages of:

a. High production rate: only seconds can finish the complete welding operation;

a. High production rate: only seconds can finish the complete welding operation;

b. High strength: comparing to glue sticking, ultrasonic welding is sticking by molten material itself, and the material infiltrate into each other, the assembly strength is the much higher.

c. Air tight: comparing to assembling by screws or buckles, ultrasonic welding can realize air-tight and leak-proof assembling, which can be applied to on products in waterproof or leakage-proof requirement.

Ultrasonic welding is widely applied in automotive industry, house-appliance industry, electronics industry, toy industry, medical consumable production industry, packing procedure area, etc.

II-2. Ultrasonic cutting is similar, it normally just design the ultrasonic horn with knife blade to work on products. Ultrasonic cutting is with net cutting result and fast cutting speed, etc, it is wide applied in different field, such as in automotive industry, it can be applied to cut tire, trim the IP cover or inner canopy, food making especially for cage cutting, packing sealing and cutting, etc.

II-2. Ultrasonic cutting is similar, it normally just design the ultrasonic horn with knife blade to work on products. Ultrasonic cutting is with net cutting result and fast cutting speed, etc, it is wide applied in different field, such as in automotive industry, it can be applied to cut tire, trim the IP cover or inner canopy, food making especially for cage cutting, packing sealing and cutting, etc.

II-3. Ultrasonic sewing or bonding: it also the same as ultrasonic sealing, which is applying ultrasonic system working on fabric. It normally applied a ultrasonic roller working together with ultrasonic horn. It design teeth or knife blade on ultrasonic roller to realize fabric ultrasonic sewing, cutting, sealing, cutting, lacing, etc. During the operation, ultrasonic horn is contacting with ultrasonic horn while the fabric is running through between horn and roller, the ultrasonic energy output transmitted to fabric under the pressure between horn and roller casing oscillation and heating to melt fabric resulting ultrasonic sealing or cutting.

II-3. Ultrasonic sewing or bonding: it also the same as ultrasonic sealing, which is applying ultrasonic system working on fabric. It normally applied a ultrasonic roller working together with ultrasonic horn. It design teeth or knife blade on ultrasonic roller to realize fabric ultrasonic sewing, cutting, sealing, cutting, lacing, etc. During the operation, ultrasonic horn is contacting with ultrasonic horn while the fabric is running through between horn and roller, the ultrasonic energy output transmitted to fabric under the pressure between horn and roller casing oscillation and heating to melt fabric resulting ultrasonic sealing or cutting.

Here we have to say that all ultrasonic sewing, ultrasonic bonding, ultrasonic fabric cutting, ultrasonic lacing, ultrasonic sealing, etc, is a type of process procedure apply ultrasonic of welding or cutting. It is with advantage of easy operation, high operation efficiency, flexible patterns design or procedure alteration.

II-4. Ultrasonic cleaning is a kind of washer art applying ultrasonic principle. It applies ultrasonic in high

II-4. Ultrasonic cleaning is a kind of washer art applying ultrasonic principle. It applies ultrasonic in high

frequency wave to generate huge quantity of tiny bubbles with big energy inside in water or other washing

agent, and the bubbles with energy hit work-pieces and explosion as tiny bombs in huge quantity to oscillate the dirt off from work-pieces.

Ultrasonic cleaning is normally applied to hardware cleaning, tableware clean, bow clean, etc, such for mould

washing, engine parts clean, motorparts clean, glasses clean, etc.Because the tiny bubble is radiate out in high

speed with no fixed direction, it can achieve the washing result to the area where others tooling can not reach, means it can wash anywhere the washing agent can reach.