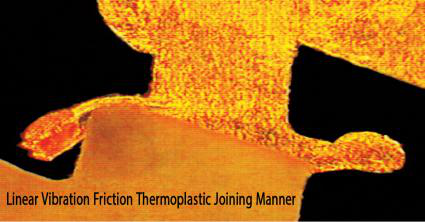

About linear vibration friction welding

by Alex Lee email: alexlee2696@163.com; Mobile/Wechat/Whatsapp: +86-15918523336

I. What is linear vibration welding?

Linear vibration welding means a kind of thermoplastic joining by friction of repeat linear vibration in high frequency. During linear vibration welding, one work-pieces is held steady normally in lower fixtures with no motion, and the other work-piece is held in a motion fixture normally upper fixture, two work-pieces are pressed together under high pressure while the motional fixture vibration in repeat linear motion to case the friction at the contacting surface of the work-pieces to case heating and melting to plastic material, then vibration stop and keep two work-pieces together under high pressure until material temperature cool down and form jointing.

Because of its high welding ability, vibration welding is mostly applied for challenging thermoplastic welding, especially in welding in big size, challenging material with requirement of high welding strength and airtightness.

Linear vibration welding mostly applied in automotive industry, house-held industry, etc.

This kind of vibration is named as electrical-magnetic vibration. Comparing the others one called mechanical vibration, which applied motor working together with cam mechanism, electrical-magnetic type vibration can easily realize frequency & amplitude control and inspection in time, achieving precision welding process control, etc.

This kind of vibration is named as electrical-magnetic vibration. Comparing the others one called mechanical vibration, which applied motor working together with cam mechanism, electrical-magnetic type vibration can easily realize frequency & amplitude control and inspection in time, achieving precision welding process control, etc.

Vibration welding can be applied for thermoplastic welding and metal welding, here we presently study the vibration thermoplastic welding only.

Linear vibration friction plastic welding is widely applied in different field of industry, especially in automotive industry, house-appliance industry, aviation equipment manufacturing industry, etc. It is with advantages of high welding ability, can be applied to weld parts in big size, complex geometric shape design and challenging material, resulting high welding strength in stable welding continuous welding performance, ensuing air-tightness in joining area.

Linear vibration friction plastic welding is widely applied in different field of industry, especially in automotive industry, house-appliance industry, aviation equipment manufacturing industry, etc. It is with advantages of high welding ability, can be applied to weld parts in big size, complex geometric shape design and challenging material, resulting high welding strength in stable welding continuous welding performance, ensuing air-tightness in joining area.

II. How is the process of vibration

Linear Vibration Welding Process:

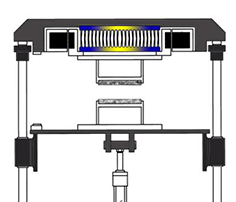

STEP 1

Manual load work-piesces to be welded into welding ;

STEP 2

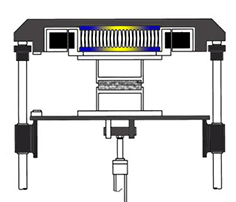

The elevating fixture ascends to press two work-pieces together by high pressure;

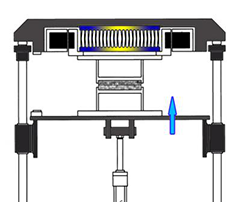

STEP 3

Vibration system starts, by the pulling energy from the electromagnets at two sides of the springs, the vibration springs oscillation forces upper jig reciprocating motion in definite frequency and amplitude, by which friction is cased at the contacting surface of two thermoplastic halves to generate heating energy, the heating energy melts the thermoplastic material at the welding line until it reach melting volume.

STEP 4

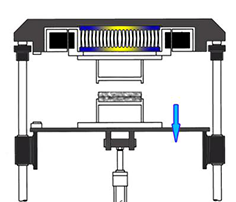

Once the thermoplastic melting volume (time or depth) reach the set value, system stops vibration, then the vibration springs returns to zero position and bring the upper fixture back to its original position, then the machine system keeps compressing two plastic together by fixtures under pressure until jointing area cools and becomes re-solidified.

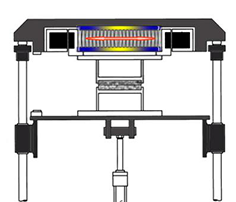

STEP 5

When the melted material at vibration joining area becomes re-solidified, the upper fixture releases the plastic part, then the elevating table descends descends to the original height, and then releases the finally welded plastic parts. The vibration welding cycle is finished, then manual remove the finished parts from vibration welding machine.