Ultrasonic Cutting

by Alex Lee from MP Sonic

The principle of ultrasonic cutting

Ultrasonic cutting is a kind of cold cutting, which applies ultrasonic energy generating vibration in high frequency to case the fracture at material. During ultrasonic cutting, the ultrasonic system converts electric energy in 50/60Hz into vibration energy in frequency of 20~40KHz typically and transfer to cutting blade, by which vibration in microscopic level is cased reducing the friction between blade and material to be cut, resulting in precise and neat cutting.

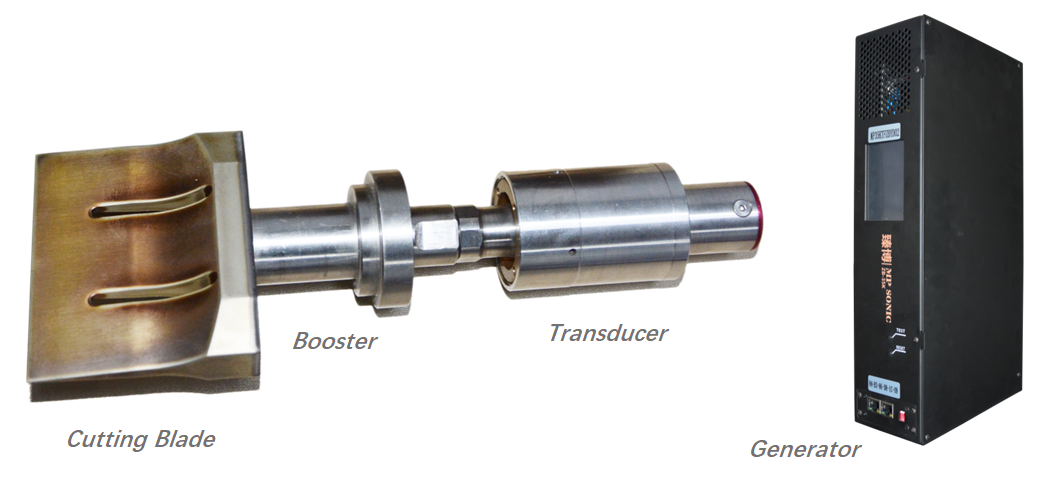

Ultrasonic generator: the system which converts supplied 50/60Hz into high frequency typically 20~40KHz. The supplied voltage 220V AC in frequency of 50/60Hz converts into high voltage signal in frequency over than 20KHz (normally 20KHz, 28KHz, 30KHz, 35KHz, 40KHz) supplied to ultrasonic transducer;

Ultrasonic transducer: a convertor which converts the high voltage electrical signal from ultrasonic generator into mechanical vibration without change the frequency. The high voltage electric signal in ultrasonic frequency from generator supplied to the Piezoelectric ceramics of ultrasonic transducer and case oscillation in the same frequency and transmits to the output terminal of transducer in amplitude;

Ultrasonic booster: as an amplifier which by a certain gain enhances the amplitude of oscillation effected by transducer in ultrasonic frequency to gain enough mechanical energy to process material;

Ultrasonic blade: the cutting tooling as a kind of sonotrode of ultrasonic system which also called as ultrasonic horn. Ultrasonic oscillation which has been amplified by booster transmitted to ultrasonic blade and case the oscillation in the same frequency to effects on work-pieces case precision and smooth cutting under force.

See more about ultrasonic cutting System >>

The benefit of ultrasonic cutting

1. Ultrasonic cutting results in neat and smooth cutting surface: The vibration in microscope level minimized the friction between ultrasonic cutting blade and material, avoiding segments or coking;

2. Precise cutting controlled: A. on one hand can minimize the wasted material to save cost; B. on the other hand realize the precision control in cutting depth & residual thickness;

3. Clean & environmental: by ultrasonic cutting there is no material segments cased by scraping to material nor smoking cases by heating or burning;

4. Low force and efficient operation: with ultrasonic vibration energy there is no request of strong force to achieve the cutting to material, the cutting is more efficient comparing normal cutting method;

5. Almost no thermal impact to material, no deformation or coking cased to material;

6. Easy in realization of automation: ultrasonic cutting can be integrated onto automatic machine to realize automatic or semiautomatic production.

Where is the ultrasonic cutting applied?

Ultrasonic cutting can be applied to

material such as rubber, thermal plastic material, composite material, leather,

silicone, asbestos, food, packing material, fabric or textile, etc. It is

widely used across various industries. Below are its primary application areas

and characteristics:

1. Food Production:

Baked food cutting such as cutting to cakes, bread, cheese, etc, which prevents sticking or deformation.

Frozen foods cutting in precision such as frozen meat, ice cream, etc., reducing crumbs.

Soft foods cutting such as the cutting to sushi, mousse, etc., maintaining structural integrity.

Advantages of food cutting by ultrasonic: no heating required, hygienic, and contamination-free with clean cuts.

2. Automotive and Aerospace

Applications:

Interior materials cutting such as the trimming to dashboard leather, headliner trimming, airbag tear-line scoring to soft skin of interior, soundproofing foam cutting, tire cutting, etc.

Composite components process such as precision machining of carbon fiber-reinforced plastics (CFRP).

Advantages of ultrasonic cutting application: burr-free cuts, minimizing delamination or material damage, precision control in cutting depth.

3. Packaging Industry

Applications:

The cutting of flexible packaging films cutting such as aluminum foil, plastic films, etc.

Sealed edge trimming such as simultaneous cutting and sealing of packaging edges.

Advantages by ultrasonic cutting principle: High speed, contamination-free, suitable for automated production lines.

4. Medical and Biotechnology

Applications:

Ultrasonic cutting applied as surgical instruments such as ultrasonic bone scalpels for precise orthopedic or neurosurgical procedures.

Medical materials cutting such as the cutting to gauze, adhesive dressings, etc., avoiding fiber dispersion.

Ultrasonic cutting applied in pharmaceuticals such as dividing tablets or soft capsules without damaging active ingredients.

Advantages of ultrasonic cutting application in medical and biotechnology: sterile, no mechanical stress, suitable for sensitive materials.

5. Rubber and Plastic Processing

Applications:

Tire Manufacturing: the cutting of rubber treads or liners (see Video).

Plastic products: the trimming of PVC pipes, silicone parts, etc.

Advantages of ultrasonic cutting method: Minimizes deformation and extends tool life.

6. Textile & Apparel Industry

Applications:

Synthetic fabrics cutting to material such as synthetic fibers, non-woven fabrics (e.g., masks, protective clothing).

Composite materials: Processing high-performance materials like carbon fiber or Kevlar.

Advantages of ultrasonic cutting application: simultaneous cutting and sealing edges, preventing fraying, and improving efficiency.

7. Electronics Industry

Applications:

Flexible Printed Circuits (FPC) precision cutting of circuit boards.

Lithium Battery Separators: Cutting electrodes or separators without short-circuit risks.

Advantages by ultrasonic cutting: No thermal deformation, ideal for thin and brittle materials.

8. Other Emerging Fields

3D printing post-processing: removing support structures or trimming models.

Eco-friendly materials: cutting biodegradable plastics without chemical contamination.

How to use ultrasonic cutting system:

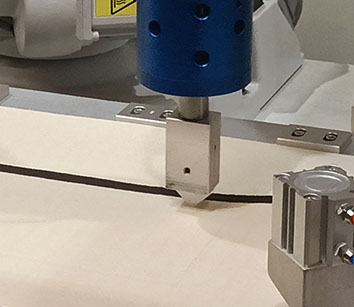

Ultrasonic cutting can be realized by handheld type which normally is in 28~40KHz or installed on automatic machine controlled by auto-action mechanical or multiple axile robot.

Videos Reference:

Frequency: ultrasonic cutting normally can be 20KHz, 28KHz, 30KHz, 35Khz, 40KHz, etc. The frequency selected normally depends on the material to be cut and power of ultrasonic cutting;

Power: ultrasonic system power for cutting normally according to the material, size and thickness to be cut. It should be noted that normally the higher is frequency of ultrasonic system, the lower is the power can gain.

Cutting tooling material: ultrasonic cutting tooling, normally need means the ultrasonic blade, means the cutting sonotrode. The cutting blade can be titanium or steel. The choice of cutting blade depends on the cutting material and cutting requirement, eg, if hard material, it normally cut by steel blade, while if it soft material or health concerned, such cake, it normally cut by titanium blade.

Moreover, for some special application, it requests special cutting blade material, such as ceramic material.