Ultrasonic Appliance to Plastic Part Process

By Alex Lee, Email: alexlee2696@163.com, Mobile/Wechate/Whatsapp: +86-15918523336

Ultrasonic applied in industries normally is 15~70KHz or over than that, the most typical ultrasonic frequency applied is 15KHz, 20KHz, 28KHz, 30KHz, 35KHz, 40KHz, 60KHz, 70KHz, etc. It applies ultrasonic generator which as an ultrasonic power supply to ultrasonic convertor, can be analogue type and IGBT type, to transform 50/60Hz electric power externally supplied into 15KHz or over and to supply to ultrasonic transducer (also called ultrasonic converter). Ultrasonic transducer then transforms the supplied electrical power by generator into mechanical energy as oscillation in the same frequency and then to transmit the energy to booster to enhance the wave amplitude by gain, after which the energy will be transmitted to ultrasonic horn (sonotrode, a part of ultrasonic welding tooling) to have it enhanced again by gain, after which then energy will work on work-pieces to process it.

Ultrasonic is widely applied in both military area, industry area or in people living, such as ultrasonic detection, ultrasonic attack, ultrasonic metal inspection, ultrasonic health examination or health treatment, ultrasonic welding (plastic welding or metal welding), ultrasonic cutting, etc. This article will describe some application of ultrasonic in plastic industry only.

I. The most application of ultrasonic to plastic parts process:

Ultrasonic applied in plastic parts process mostly including ultrasonic welding, ultrasonic spot welding, ultrasonic stacking / riveting, ultrasonic cutting, ultrasonic punch, ultrasonic forming, ultrasonic inserting, etc, because of its advantages of high efficiency and perfect process result

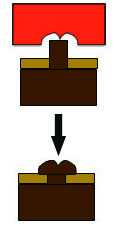

I-1. Ultrasonic plastic welding:Press two pre-assembled plastic halves together by ultrasonic horn under high pressure, and ultrasonic horn transmits energy to the welding area through the one plastic half touched by ultrasonic horn, by which friction cased of internal of plastic material to generate high temperature to melt the plastic material at the welding area, then ultrasonic stops but keep plastic halves pressed together by ultrasonic horn under pressure until re-solidification of plastic part, then ultrasonic plastic welding finishes.

I-1. Ultrasonic plastic welding:Press two pre-assembled plastic halves together by ultrasonic horn under high pressure, and ultrasonic horn transmits energy to the welding area through the one plastic half touched by ultrasonic horn, by which friction cased of internal of plastic material to generate high temperature to melt the plastic material at the welding area, then ultrasonic stops but keep plastic halves pressed together by ultrasonic horn under pressure until re-solidification of plastic part, then ultrasonic plastic welding finishes.

This application of ultrasonic is popular in automotive industry, motorbike industry, house-held applicant industry, electronics industry, toy industry, etc. It is with advantages of firm welding strength, leak-proof welding performance and high production capacity, etc

.

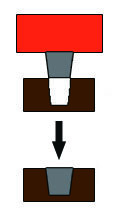

I-2. Ultrasonic riveting also is described as ultrasonic stacking, it means a ultrasonic horn works on the top of plastic probe under pressure, to melt the plastic material and form buckle at the top, by ultrasonic oscillation, then ultrasonic stop working and keep horn pressing onto the probe under pressure until the plastic buckle become re-solidified, the ultrasonic riveting (stacking) finish and achieve plastic stacking assembly.

I-2. Ultrasonic riveting also is described as ultrasonic stacking, it means a ultrasonic horn works on the top of plastic probe under pressure, to melt the plastic material and form buckle at the top, by ultrasonic oscillation, then ultrasonic stop working and keep horn pressing onto the probe under pressure until the plastic buckle become re-solidified, the ultrasonic riveting (stacking) finish and achieve plastic stacking assembly.

Ultrasonic plastic stacking assembly procedure is widely applied in automotive industry, electronics industry, house-held applicants industry, etc, especially automotive industry, such as ultrasonic riveting on door panel of vehicle for assembly, audio equipment riveting assembly, etc.

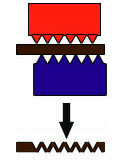

I-3. Ultrasonic spot welding also is described as ultrasonic puncture welding, during which, the ultrasonic energy is focused onto the tooth of ultrasonic horn at its top, through which the ultrasonic is forced onto one of plastic half. By ultrasonic plastic spot welding, the ultrasonic energy punctures the plastic half touched by horn by the horn tooth and transmits to the other plastic half at the processed area, then plastic melding generated by high temperature because of ultrasonic energy at the puncture area, after that, ultrasonic stop and keep two plastic halves pressed together under pressure by ultrasonic horn until plastic re-solidification at the puncture area, then ultrasonic plastic spot welding is finished. Ultrasonic plastic spot welding is requested for Assembly of two plastic halves which doesn't requests leak-proof by requests large welding area to ensure welding strength. By this kind of plastic welding, the surface of two plastic halves should fit and superimposed together at the spot welding area, and it requests the thickness of the punctured plastic half at the punctured area should not too thick (normally no more than 3mm).

I-3. Ultrasonic spot welding also is described as ultrasonic puncture welding, during which, the ultrasonic energy is focused onto the tooth of ultrasonic horn at its top, through which the ultrasonic is forced onto one of plastic half. By ultrasonic plastic spot welding, the ultrasonic energy punctures the plastic half touched by horn by the horn tooth and transmits to the other plastic half at the processed area, then plastic melding generated by high temperature because of ultrasonic energy at the puncture area, after that, ultrasonic stop and keep two plastic halves pressed together under pressure by ultrasonic horn until plastic re-solidification at the puncture area, then ultrasonic plastic spot welding is finished. Ultrasonic plastic spot welding is requested for Assembly of two plastic halves which doesn't requests leak-proof by requests large welding area to ensure welding strength. By this kind of plastic welding, the surface of two plastic halves should fit and superimposed together at the spot welding area, and it requests the thickness of the punctured plastic half at the punctured area should not too thick (normally no more than 3mm).

Ultrasonic spot welding procedure is widely applied in automotive area, health-care products industry, living good production, garment industry, etc, such as the ultrasonic spot welding for IP (dash pad) of vehicle, engine cover, sound-insulation cloth, bumper, spoiler, splasher, etc in automotive industry, and fabric or nonwoven ultrasonic sealing for mask, insulation cloth, ice pack, bed cover, ultrasonic sewing for garment, etc.

I-4. Ultrasonic inserting is a technology inserting metal pieces, such as metal screw or nut, into plastic hole. During ultrasonic inserting, the ultrasonic energy by oscillation is transmit to metal pieces by horn under pressure, by which high temperature cased by friction generated by ultrasonic oscillation and have the plastic material around metal pieces molten, while the metal pieces is pressing into plastic hold, then ultrasonic stops working. After plastic material is re-solidified, the metal pieces is hold by plastic hold firmly in high strength.

I-4. Ultrasonic inserting is a technology inserting metal pieces, such as metal screw or nut, into plastic hole. During ultrasonic inserting, the ultrasonic energy by oscillation is transmit to metal pieces by horn under pressure, by which high temperature cased by friction generated by ultrasonic oscillation and have the plastic material around metal pieces molten, while the metal pieces is pressing into plastic hold, then ultrasonic stops working. After plastic material is re-solidified, the metal pieces is hold by plastic hold firmly in high strength.

Ultrasonic inserting is mostly applied to insert screw or nut into plastic parts for latter assembly. It can be applied in many kinds of plastic industry, such as for assembly production of mobile phone, computer parts, television set, parts of vehicle, etc. But because of its limit in operation and power output, the operation efficiency is low, and this kind of application is not widely applied.

I-5. Ultrasonic plastic forming means applying profile moulding ultrasonic horn to soften or melt plastic pieces by ultrasonic oscillation energy, then keep the plastic pieces pressed by ultrasonic horn under pressure after ultrasonic stops until the molten plastic material becomes re-solidified and the shape is formed.

I-5. Ultrasonic plastic forming means applying profile moulding ultrasonic horn to soften or melt plastic pieces by ultrasonic oscillation energy, then keep the plastic pieces pressed by ultrasonic horn under pressure after ultrasonic stops until the molten plastic material becomes re-solidified and the shape is formed.

Comparing with other application of ultrasonic, ultrasonic plastic forming is not so popular in today period. It mostly applied for plastic products such as direction.

I-6. Ultrasonic cutting means applying ultrasonic oscillation energy to cut objects, during which, the ultrasonic energy is focus on knife-like tooling to realize cutting. Comparing with traditional cutting, ultrasonic cutting no need heavy external force, and its cutting is beautiful with no fragment. Ultrasonic cutting can be applied in fabric cutting, plastic cutting, rubber cutting, food cutting, such as cutting for garment, air-tube cutting, tire cutting, cake cutting, etc.

I-6. Ultrasonic cutting means applying ultrasonic oscillation energy to cut objects, during which, the ultrasonic energy is focus on knife-like tooling to realize cutting. Comparing with traditional cutting, ultrasonic cutting no need heavy external force, and its cutting is beautiful with no fragment. Ultrasonic cutting can be applied in fabric cutting, plastic cutting, rubber cutting, food cutting, such as cutting for garment, air-tube cutting, tire cutting, cake cutting, etc.

Ultrasonic plastic punching is a kind of ultrasonic cutting, means applying ultrasonic energy to punching hole through plastic material. For ultrasonic plastic punching, the ultrasonic horn or the base mould will be designed as punching tooling as hole shape design. During ultrasonic plastic punching, the ultrasonic energy will be focused on to the tooling blade to melt through the plastic pieces at the punching place under pressure.

Comparing with additional punching procedure, ultrasonic plastic punching is with advantages of beautiful punching & high punching ability. Ultrasonic plastic punching is applied mostly in automotive industry, specially such as punching on front / rear fender of vehicle for radars. Also it is applied to cutting the injection moulding follow flush material because of its advantages of net process result and high process efficiency.

iBORTECH provides you ultrasonic technology in different application procedure, please feel free to contact us if you are in any need of help concerned to ultrasonic technique.

II. The Jointing Performance of Plastic Material by Ultrasonic:

The welding performance by ultrasonic to different material is different. Some material can be welded very good by ultrasonic, such as ABS, while some material can not be welded very good, or never welding, because of different material characteristics & properties. The below table is for your reference when you consider ultrasonic welding procedure.

III. The advantages of Assembly Art by Ultrasonic Welding, Spot Welding, Stacking or Riveting

Compared to glue or screw assembly, ultrasonic welding has below features:

1) Fast: ultrasonic welding capacity is much higher, normally, ultrasonic oscillation itself only requests no more than 1S (normally 0.2~0.6S per welding), including the time spending in machine action and holding time, normally the cycle time is 3~5S per cycle (not including the time for operator action);

2) Leak-proof: ultrasonic welding can achieve leak-proof & airtight standard;

3) High assembly strength: ultrasonic welding is in high strength in stability, it can with heavy tension and high pressure;

4) Economy: ultrasonic welding assembly requests no accessory parts or material (such as screw, glue, etc). And because of its high production capacity, it can help save labor. Then the total production cost is reduced much.

Compering to other welding procedure such as hot plate welding, vibration welding, etc, ultrasonic is with advantages of:

1) precision welding: the welding precision is high which fit for high requirement in welding precision:

2) Beautiful welding outlook: ultrasonic welding has little imp action to plastic parts, with a reasonable jointing design, ultrasonic can achieve very nice welding outlook;

3) Lower power consumption: ultrasonic system has high energy conversion efficiency, and since the ultrasonic oscillation time is short per cycle of welding, the average power consumption is low;

4) Environmentally: comparing to hot plate welding or infrared welding, ultrasonic generates no smoke or fog, compare to vibration welding, ultrasonic welding has very low or no noise (note: ultrasonic system lower than 20KHz generate some sound, ultrasonic frequency higher than 20KHz is not audible).

IV. Process Steps of Ultrasonic Plastic Welding

For ultrasonic plastic welding, normally, the operation process as below steps:

Step 1

Manual assemble two plastic pieces together and then load them into base fixture;

Not: for precision welding, it normally requests matching limit design on plastic parts;

Step 2

Ultrasonic horn descents and presses onto the upper plastic pieces under pressure;

Step 3

Ultrasonic system works to transmit ultrasonic energy by oscillation to plastic part by horn, the friction internal of plastic material at welding area cases heating to melt the jointing line;

Step 4

When ultrasonic oscillation finishes (ultrasonic oscillation can be controlled by time mode or energy mode), then it stop working and keep horn pressing onto upper plastic pieces under pressure until the molten material become re-solidified, then plastic jointing is formed;

Step 5

Ultrasonic horn ascend to release plastic parts, ultrasonic welding is finished, and manual take out plastic products from base fixture.

ultrasonic plastic welding by standard plastic welding machine is in very easy operation process, which makes ultrasonic plastic assembly in very high production capacity. Because of its advantage of high efficiency, ultrasonic welding is more and more welcomed in different industry.