The production of cup mask, especially mask in quality standard >= N95, concerned to complex process procedure because of complicated mask design and different material characteristics.Here we share how cup mask make and what is the critical at different process steps.

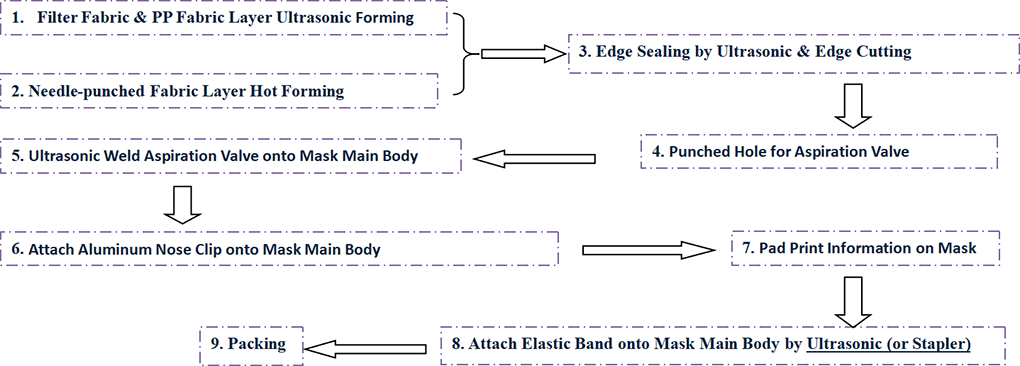

Process Flow:

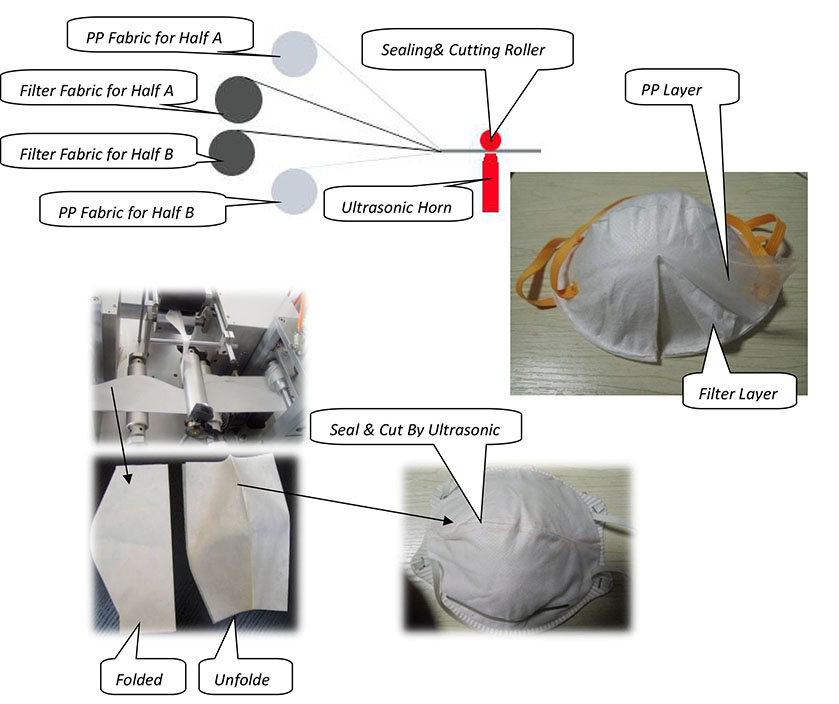

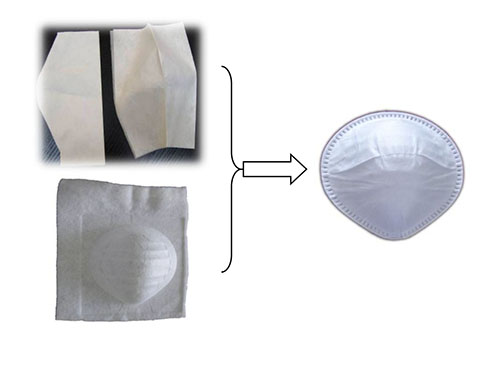

I.Filter Fabric & PP Fabric Layer Ultrasonic Forming

Form the outer layer (PP fabric Layer) and middle layer (Filter Layer) into 3D shape and cut extra material by ultrasonic.

Material: 1. Filter layer normally is made of melt-blown fabric or activated carbon fabric (can applied both), this layer is the critical layer for masks filtration and aspiration function;

2. PP layer is made of PP non-woven fabric. This layer is to protect filter layer;

Critical: Melt-blown / activated fabric can’t be process by high temperature under pressure, or it will change the fabric construction which will change its percentage of filtration and aspiration. This layer must be formed by ultrasonic but hot by hot forming.

The material content and GMs will affect the mask performance on protection and aspiration.

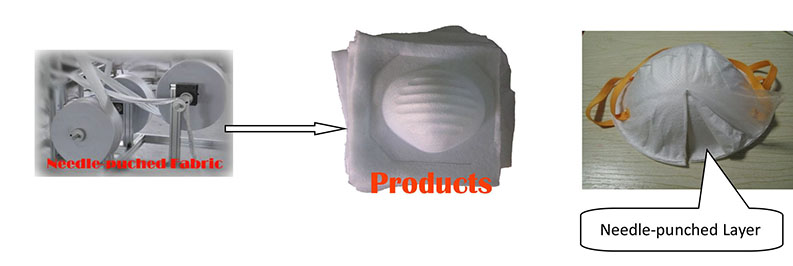

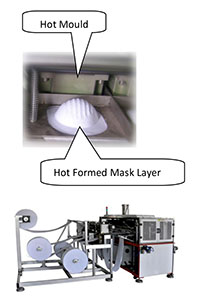

II. Needle-punched Fabric Layer Hot Forming

Form hard cup-like layer by high temperature from Needle-punched fabric under pressure. This layer is the framework of mask.

Form hard cup-like layer by high temperature from Needle-punched fabric under pressure. This layer is the framework of mask.

Critical:

1) Ensure even thickness of hot formed needle-punched layer;

2) Ensure enough hardness to keep the cup-like shape;

3) Keep material from sticking onto hot mould;

4) Keep it from distortion during collection after hot forming;

5) The material contents and GMS will fix the hardness and softness;

6) Mold precision and temperature will define the forming performance.

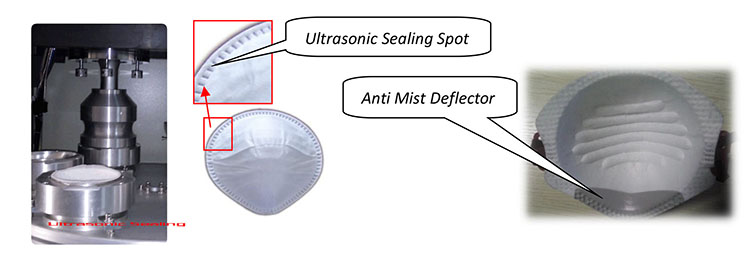

III. Seal all Layers by Ultrasonic and Cut off Extra Fabric Material by Cold Knife

After needle-punched fabric layer, filter layer and PP layer are formed, it requests to seal them together around and cut extra fabric material at edge.

After needle-punched fabric layer, filter layer and PP layer are formed, it requests to seal them together around and cut extra fabric material at edge.

If the anti mist deflector is requested to attached by ultrasonic, it can finished at this step.

Critical: 1. it requests to pre-fit different layers together well and tightly before sealing to ensure outlook;

2. Enough ultrasonic power and reasonable ultrasonic sealing design is requested to ensure sealing quality;

3. Cutting unit design is concerned to cutting performance and knife duration.

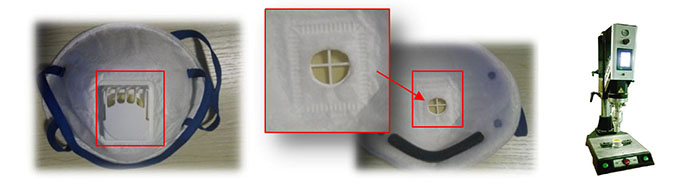

IV. Punched Hole for Aspiration Valve

If the respirator mask is designed with aspiration valve, it requests to punch hold on mask for valve assembly.

If the respirator mask is designed with aspiration valve, it requests to punch hold on mask for valve assembly.

Critical: 1. Punching moulds and machine power design precision will affect punching performance;

2. Moulds material and process will affect mould duration.

V. Ultrasonic Weld Aspiration Valve onto Mask Main Body

Normally, you can select to assemble aspiration valve onto mask by ultrasonic welding or non-welding through your valve design, however, for better leakage-proof, it suggests ultrasonic welding assembly.

Critical: Ultrasonic power, mould design, valve design and valve material will affect welding performance.

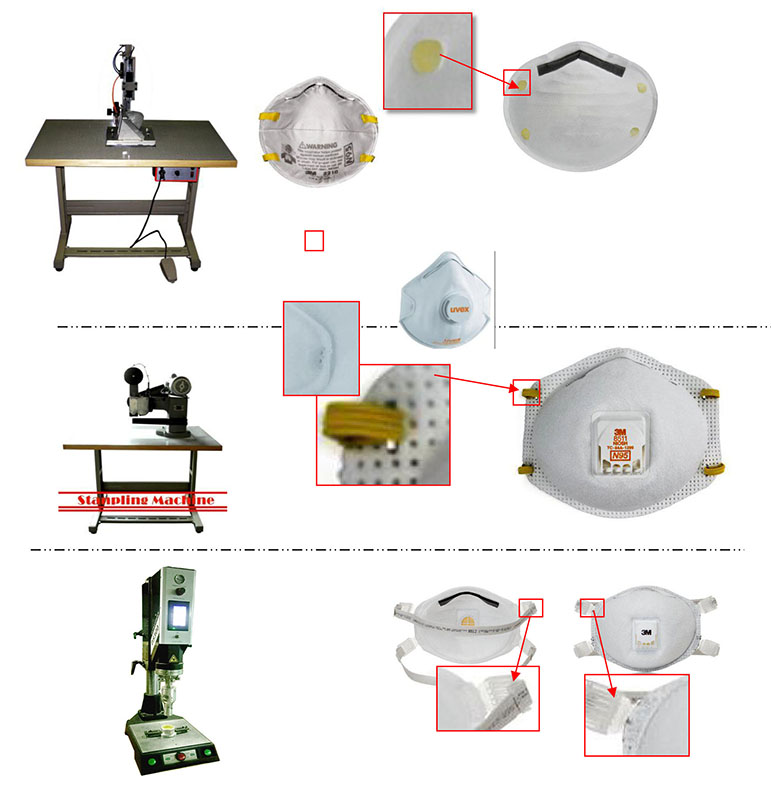

VI. Attach Aluminum Nose Clip onto Mask Main Body

Aluminum nose clip is requested to fit mask with nose to keep leakage-proof and reach the best protection (some mask applied plastic clip with metal wire inside). On the back of aluminum clip piece, there is solid glue which will be molten by heating. Thus a heat sticking machine is applied to heat the aluminum and keep pressing it onto mask until cold reaching sticking.

Critical: 1. The thickness of aluminum clip will confirm the clip strength;

2.The heating temperature affects the sticking performance.

VII. Pad Print Information on Mask

Normally, the mask specification information, brand logo, contact, etc is printed onto mask by pad printing. Also some makes design logo on valve injection moulds or make logo on valve by laser or printing.

Normally, the mask specification information, brand logo, contact, etc is printed onto mask by pad printing. Also some makes design logo on valve injection moulds or make logo on valve by laser or printing.

Critical: Printing size and color numbers will fix the equipment specification and cost.

VIII. Attach Elastic Band onto Mask Main Body by Ultrasonic or stapler

Normally, if is wants to attached elastic band onto mask directly (not using buckle), it can apply ultrasonic welding or stapling.

If use fabric type elastic band, it suggest use ultrasonic, if rubber band or other material type which can’t be processed by ultrasonic, it requests stapling machine to staple it onto mask.

Critical: elastic material specification affect attaching performance and shrink rate, but also affects cost much.

Addtinal:

Some lower level respirator mask use anti mist deflector foam which there is glue on back, it requests to stick it onto mask by hand, but no need equipment requested.

Download:Respirator Mask Production Procedure Deatail

Look for: Cup Mask Production Line